2 Experimental program

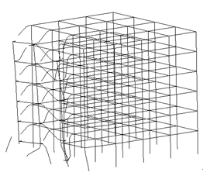

2.1 The proposed MHRPC frame

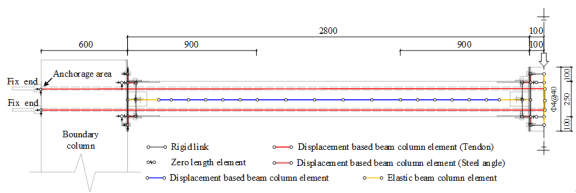

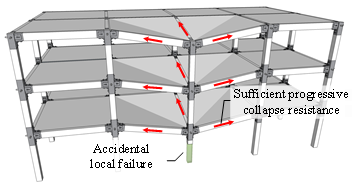

In this study, we intend to introduce the MHRPC frame system for improving both seismic and progressive collapse performances of RC frames. A schematic of the proposed MHRPC frame is shown in Figure 1, in which Figure 1b depicts the details of the beam-column joint region. The structure is assembled using precast RC beams and columns, unbonded PT tendons, energy dissipating steel angles and large rotational shear plates. It should be noted that when the structure is exposed to a specific hazard, one or more of the components may not play a major role. However, these components will become critically important to improve the structural resistance against other hazardous events. With respect to the seismic action, published experimental studies indicated that the proposed structure has a favorable self-centering capacity, minor post-earthquake damage and is easy to repair after the earthquake [14-17]. Under an earthquake scenario, the prestressing tendons, steel angles and shear plates work together to resist the seismic action. More specifically, adequate flexural strengths can be provided by the steel angles and PT tendons while sufficient shear strengths can be provided by the shear plates and PT tendons. In addition, the steel angles also serve as the energy dissipating devices, which are designed to be replaceable after the earthquake. The PT tendons also provide the self-centering capacity to the structure. When considering the progressive collapse resistance, the structure is expected to deform as shown in Figure 1a. At small deformations, the progressive collapse resistance is also provided by the flexural capacities of the beams and the compressive arch action. While at large deformations, both the steel angles and PT tendons are under tension and provide the catenary resistance to redistribute the unbalanced gravity load. The shear plates at the joint region are designed with a slotted hole to accommodate large rotation between the precast columns and beams and help to redistribute the unbalanced load. Hence, the proposed MHRPC system could provide sufficient progressive collapse resistance and alternate load paths, thereby preventing propagation of the initial failure and disproportionate collapse of the entire structural system.

|

|

(a) Deformation of MHRPC frame under column removal scenario |

|

|

(b) Details of the beam-column joint |

Figure 1. Schematic of the MHRPC frame

2.2 Experimental design

2.2.1 Design of the prototype building

In order to verify the seismic and progressive collapse performance of the proposed MHRPC frame, a six-story RC frame with a seismic design intensity of VI (i.e., the design peak ground acceleration (PGA) with a 10% probability of exceedance in 50 years is equal to 0.05g) is taken as the prototype building. Note that this prototype building has been thoroughly studied experimentally and analytically by Lin et al. [10], Ren et al. [19], and Lu et al. [20]. Three different frame structures are derived from the design, i.e., a conventional RC frame, an RC frame after implementing the progressive collapse design and a newly proposed MHRPC frame, designated as RC6, RD1, and PC6, respectively. Both cyclic tests and progressive collapse tests are conducted to compare the seismic resistance, residual deformation and progressive collapse resistance of these frames.

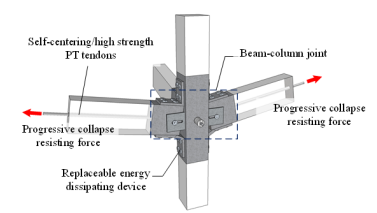

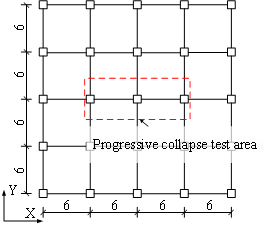

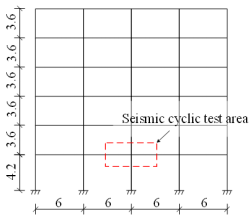

Detailed dimensions of the six-story RC frame are shown in Figure 2. The span lengths in both longitudinal and transverse directions are 6 m. The structure is considered to be fully fixed to the ground. The dead load considered on each story is 5.0 kN/m2, whereas the live load is 2.0 kN/m2. More detailed information about this prototype building have been reported by Lin et al. [9], Ren et al. [19], and Lu et al. [20]. Initially the structure is designed following the Chinese design codes (i.e., the Code for Design of Concrete Structures [21] and the Code for Seismic Design of Buildings [22]) to create the conventional RC frame, i.e., RC6.

|

|

|

(a) Plan view |

(b) Elevation |

Figure 2. Layout of the six-story RC frame (unit: m)

2.2.2 Progressive collapse design of RD1

In the previous work of Lin et al. [10], nonlinear dynamic analyses of RC6 were conducted to evaluate the structural progressive collapse responses. The numerical results indicated that the prototype building would collapse under gravity load by removing any one of the columns on the first to the fifth story. Some of the typical collapse scenarios are provided in Figure 3 [10]. The outcome of this previous study suggests that RC6 does not satisfy the progressive collapse resistance requirement that is specified in DoD 2010 [11], GSA 2013[12] and the Chinese code (i.e. the Code for Anti-collapse Design of Building Structures [13]) and should be strengthened to prevent progressive collapse from happening. Note that many existing studies have proved that increasing the seismic design could also enhance the progressive collapse resistance of RC frames [10, 23]. However, the influence of the higher intensity seismic design on the improvement of the progressive collapse resistance cannot be quantified, making it hard to determine the required amount of improvement for a seismic design in order to meet the demand of progressive collapse resistance. In contrast, when the design method specified in the progressive collapse design codes is used, the improved progressive collapse resistance of a structure can be determined in a more quantitative way. For the reasons given above, RC6 is redesigned according to the tie force method provided in DoD 2010 [11] and the new structure is named as RD1.

|

|

|

|

(a) Corner column |

(b) Edge column |

(c) Interior column |

Figure 3. Collapse modes of RC6 under column removal scenarios on 1st floor (Gravity load: 1.0g) [10]

A successful progressive collapse design includes improvements in both load carrying and deformation capacities. For RC frames, the load carrying mechanisms are represented by the flexural action and compressive arch action at small deformations (beam mechanism) and the catenary action at large deformations (catenary mechanism). All the above actions help to provide alternate paths to redistribute the unbalanced load when a localized failure occurs. The deformation capacity, on the other hand, demands the structure to accommodate large deformations without losing its integrity, by which progressive collapse can be prevented. For example, a 0.20 rad of chord rotational capacity is required for RC frames as specified in DoD 2010 [11].

RD1 is designed according to the tie force method specified in DoD 2010 [11] and the required tie strength is:

|

(1) |

in which, WF is the floor load, which can be derived from Equation 2; L1=6 m is the distance between the centers of the columns.

|

(2) |

The design tie strength is calculated as:

|

(3) |

in which, f = 0.75 is the strength reduction factor as specified in DoD 2010; 1.25 is the over-strength factor for the rebar, as per ASCE 41 [24]. According to DoD 2010, the design tie strength must be greater than or equal to the required tie strength:

|

(4) |

|

|

(5) |

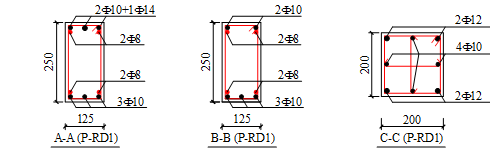

For the prototype building considered in this study, HRB 335 (fy=300 MPa) rebar is used. The calculated As = 448 mm2/m. Hence, the resulting reinforcement area within a single span is 448¡Á6=2688 mm2. After calculating the original longitudinal reinforcement within the span, the required reinforcement would become 678 mm2 (HRB 335). After scaling, the required reinforcement in the specimens of RD1 would be 189 mm2 (HPB 300, fy=270 MPa). Hence, four 8mm-diameter bars (As=201 mm2) in total are added to Specimens of RD1. Note that the progressive collapse resistance of RD1 is also re-evaluated to be safe under different column removal scenarios [10].

Furthermore, PC6 is designed by changing the frame beams and columns in RC6 to precast members and keeping the reinforcing details unchanged. These precast beams and columns are then assembled with PT tendons, energy dissipating steel angles and shear plates.

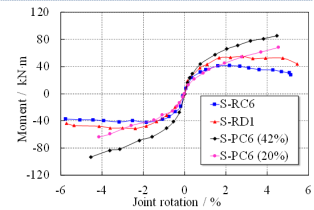

To compare the seismic and progressive collapse performances of the abovementioned three frames, two substructures enclosed by the red dash lines in Figure 2 are extracted from the building for seismic cyclic and progressive collapse tests. For the seismic cyclic tests, the specimens representing the three frames are designated as S-RC6, S-RD1, and S-PC6, respectively. For the progressive collapse tests, the specimens are named as P-RC6, P-RD1, and P-PC6, respectively.

For both the seismic cyclic tests and the progressive collapse tests, a 1/2-scale ratio is adopted for the specimens. Published research confirmed that the critical scaling factor for RC specimens not damaging in shear is 1/4, which can well represent the resistance mechanisms and load-displacement relations of large scaled structures [25]. Hence, 1/4 [26-28], 1/3 [29-30] and 1/2 [31-33] scales were adopted in many progressive collapse tests on RC substructures. Furthermore, the 1/2-scale has been very commonly used in many published cyclic tests of beam-column joints [34-36]. Abrams [25] and Yu et al. [37] also indicated that the size effects on the collapse mechanism and resistance could be neglected when testing 1/2 scaled specimens. This provides a rationale for undertaking 1/2-scale tests in the present study.

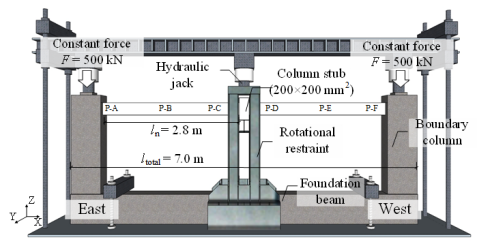

2.3 Experimental setup

2.3.1 Seismic cyclic tests

There are many successful engineering realization of slab construction in prefabricated structures which can be used as references for the proposed MHRPC system [38]. For the purpose of not further complicating the present development work, this study does not take the slabs into consideration. Nevertheless, further studies will be conducted to investigate how the slab construction will affect the performance of the proposed MHRPC frame.

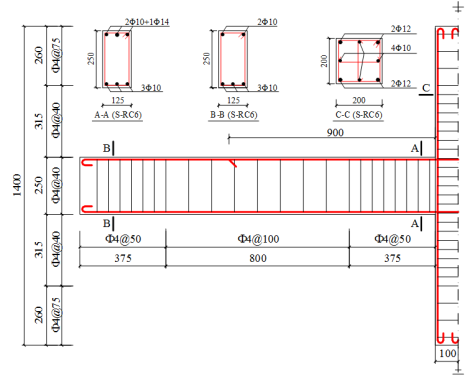

The reinforcing details of the three seismic cyclic test specimens are shown in Figures 4 and 5. In addition to the reinforcement of S-RC6 (Figure 4a), two pairs of 8 mm rebars are added to the top and bottom of the frame beams in S-RD1 after performing the progressive collapse design specified in DoD 2010 [11]. The typical sectional details of S-RD1 are given in Figure 4b, which reflects the major differences between Specimens S-RC6 and S-RD1. Details of the proposed MHRPC frame specimen (i.e., S-PC6) are shown in Figure 5. The primary design principles of this specimen are:

|

|

(a) Reinforcement details of Specimen S-RC6 |

|

Note: Plain round bars were used in all the specimens. |

|

(b) Reinforcement details of Specimen S-RD1 |

Figure 4. Details of the seismic cyclic test RC specimens (unit: mm)

|

Note: Plain round bars were used in all the specimens. |

|

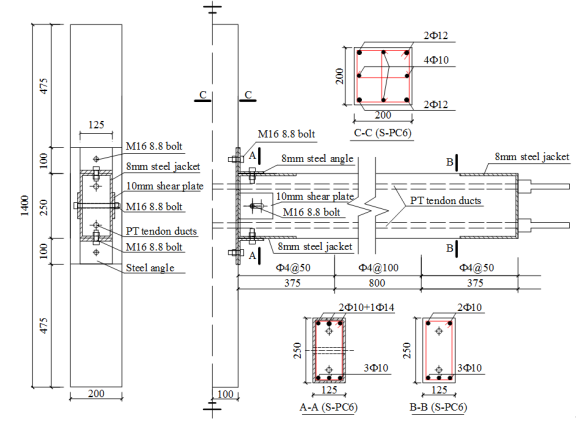

(a) Details of Specimen S-PC6 |

|

|

(b) Dimensions of the steel jackets |

Figure 5. Details of the seismic cyclic test PC specimen (unit: mm)

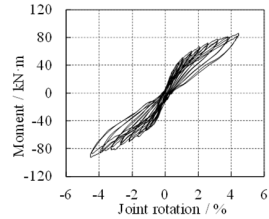

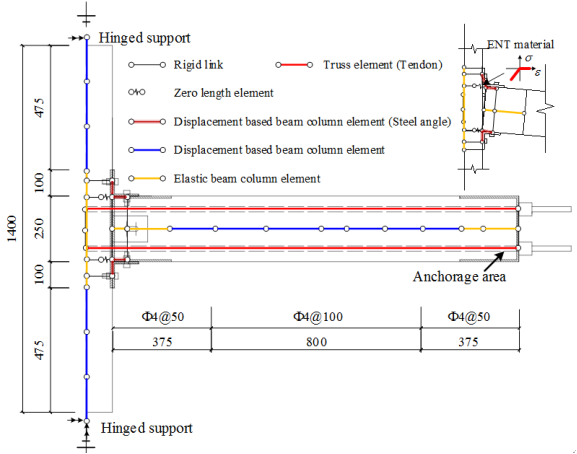

(1) Keeping the reinforcing details of the precast beams and columns identical to those of Specimen S-RC6.

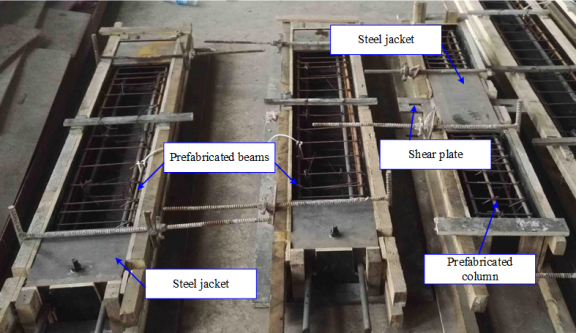

(2) Following the structural detailing adopted by Song et al. [16] and Lu et al. [17], the beam-column joint region is covered by 8 mm-thick steel jackets to prevent local compression failure as shown in Figures 5 and 6. The steel jackets are welded using steel plates and cast together with the beams. The main functions of the steel jackets are: (i) preventing the local compressive failure of the concrete at the beam-column interface; (ii) providing connections between the prefabricated beams and columns; (iii) serving as formwork during the construction of the beams (Figure 6).

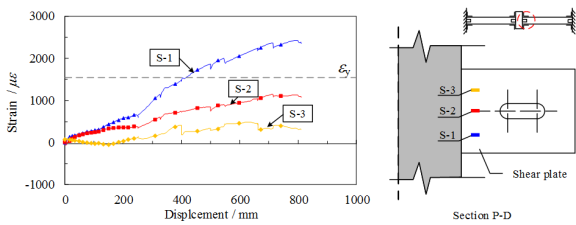

(3) According to the Chinese design code (i.e., the Technical Specification for Concrete Structures Prestressed with Unbonded Tendons) [39], two 12.7 mm PT tendons with a design tensile strength of 1860 MPa are inserted in the specimens as shown in Figure 5. The minimum prestressing force is determined following ACI 550.3-13 to provide a required level of self-centering capacity, which requires the flexural strength provided by the tendons being larger than that provided by the steel angles [40].

(4) According to the design principle specified in ACI 550.3-13 [40], the ratio of the moment provided by the energy dissipating devices to the total flexural strength shall not exceed 0.5 for both positive and negative moments. Consequently, steel angles L100¡Á100¡Á8 with a thickness of 8 mm are selected as the top and seat angles and bolted to the precast beams and columns with M16 grade 8.8 bolts.

(5) The shear plate is 10mm in thickness. The slotted hole on the shear plate allowing large deformations of the frame beams has a diameter of 18mm and a length of 53mm, which meets the deformation demands (i.e., chord rotation is equal to 0.20 rad) in the progressive collapse tests. The steel shear plates were welded to the steel jackets of the prefabricated columns, as shown in Figures 5b and 6. Note that since the beam ends are covered by the steel jackets and the shape of which are adjustable, it is not necessary for the beams to be narrower than the respective column sides.

Figure 6. Formwork of the prefabricated components

The experimental setup for the seismic cyclic test is depicted in Figure 7a. The specimens are pinned at both ends of the column. The distance between the hinge supports is 1.8 m.

|

|

(a) Setup for seismic cyclic test |

|

|

(b) Setup for progressive collapse test |

Figure 7. Experimental setup

For the seismic cyclic tests, the applied axial force is calculated according to the design axial force ratio of the column. The design axial force ratio of the middle column on the first floor is 0.85 according to the design software (the maximum axial force ratio limit for the prototype building with a seismic design intensity of VI is 0.9). Therefore, the calculated axial load is:

|

(6) |

in which, fc =14.3 MPa is the design strength of grade C30 concrete; A = 0.4 m ¡Á 0.4 m is the area of the frame column in the prototype building; SL=2 is the scaling factor. Note that in order to keep identical boundary conditions for all the S-series specimens, this axial load was used in all the seismic cyclic tests.

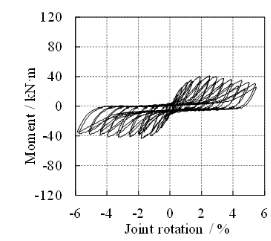

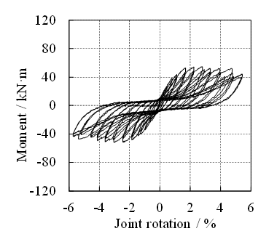

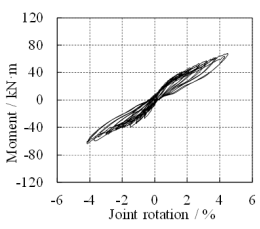

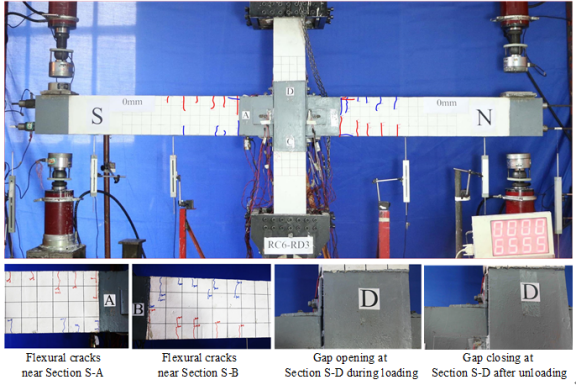

During seismic cyclic tests, a constant vertical force of 486 kN, corresponding to the design axial force ratio of 0.85, is firstly applied to the top of the column to simulate the load transferred from the upper stories. After that, the seismic forces are simulated by gradually increasing the cyclic loads at the beam ends. The loading points on the beams are 1.5 m away from the joint center. Displacement-based loading method is adopted in the tests and each level of displacement after the third cycle is cycled twice to assess the deterioration effect. The loading protocol of the seismic cyclic tests is provided in Figure 7a, which depicts the displacements at the south loading point of the S-series specimens (i.e., S-RC6, S-RD1 and S-PC6).

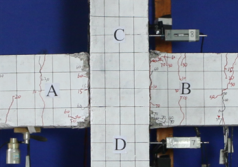

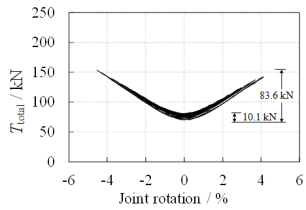

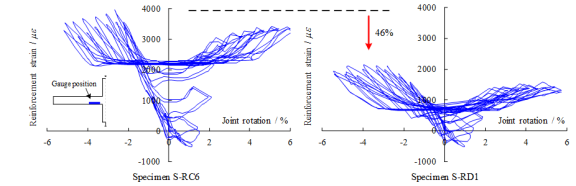

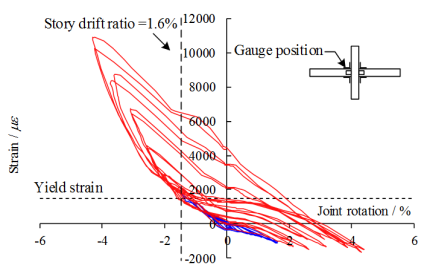

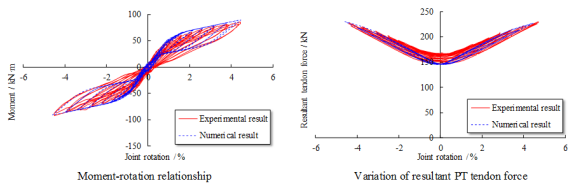

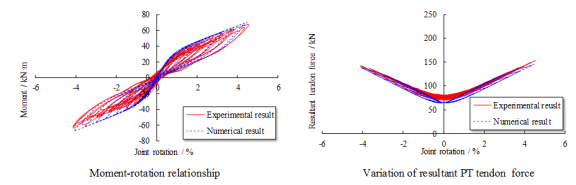

The relative rotation between the beam and column is calculated by measuring the displacements at the beam ends. The moments (i.e. M) and the joint rotations (i.e. q) of the specimens are calculated following Equations 7 and 8, respectively:

|

(7) |

|

|

(8) |

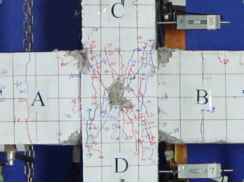

in which FS and FN are the forces recorded at the south and north loading points, respectively; dS and dN are the corresponding displacements; lF is the distance between the loading point and the joint center as shown in Figure 7a. For the convenience of describing the experimental results, four typical sections (Sections S-A to S-D) are defined on the joint specimen as shown in Figure 7a.

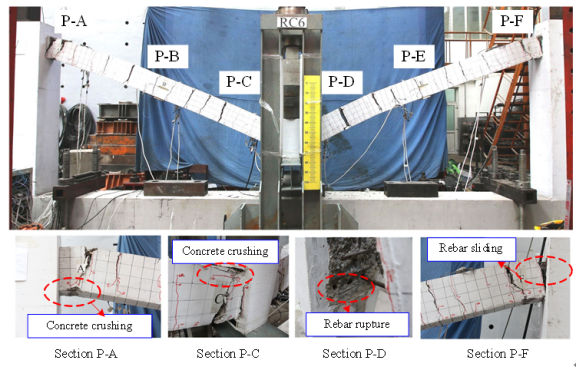

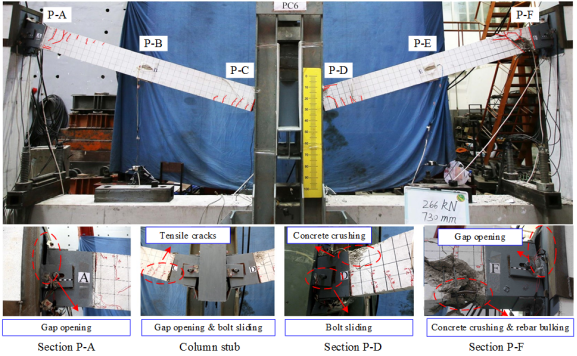

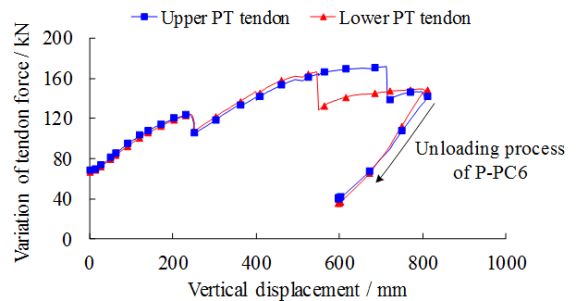

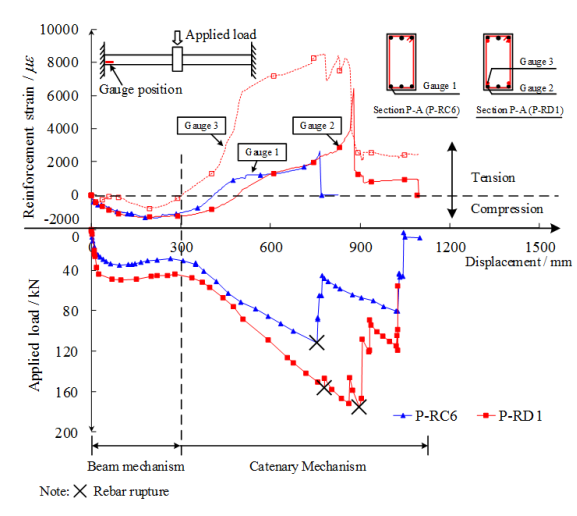

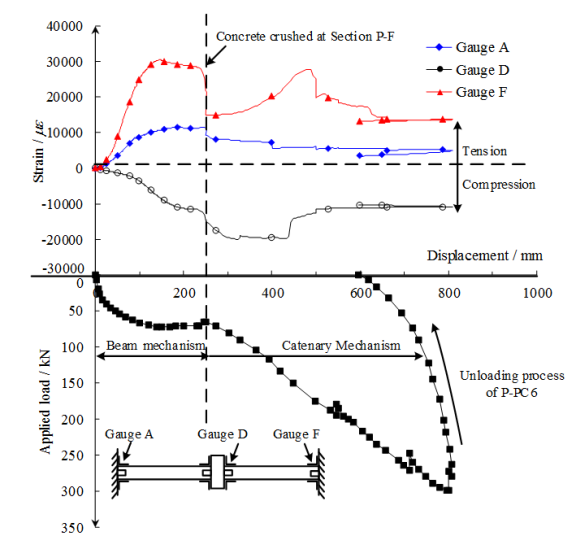

2.2 Progressive collapse tests

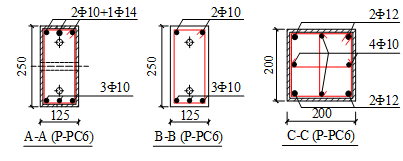

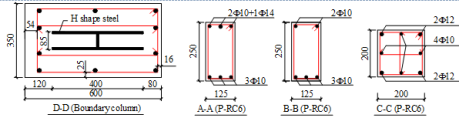

A two-span substructure on the first floor of the prototype building, which is enveloped by the red rectangle in Figure 2a, is chosen as the research object in the progressive collapse tests (Figure 6b). The reinforcing details of the tested specimens are shown in Figure 8, of which Figure 8a depicts the reinforcing details of Specimens P-RC6 and P-RD1. Figure 8b presents the details of the MHRPC specimen P-PC6. In order to ensure the strength of the boundary column, H-shaped steel is embedded in the boundary column of the specimens, as shown in Figure 8a. Note that for Specimen P-PC6, two 8 mm steel plates were cast together with the boundary columns as shown in Figure 8b. Their main function is to prevent the concrete compressive failure of the boundary columns. In a real case of the proposed MHRPC frame construction, the beam ends and the columns are also in contact with the steel jackets. Therefore, we use the steel plates at the interface area between the beams and the boundary columns to ensure the boundary conditions of the experimental tests being similar to the real situation.

|

|

|

|

(a) Reinforcement details of Specimens P-RC6 and P-RD1 |

|

|

|

Note: Plain round bars were used in all the specimens. |

|

(b) Details of Specimen P-PC6 |

Figure 8. Details of the progressive collapse test specimens (unit: mm)

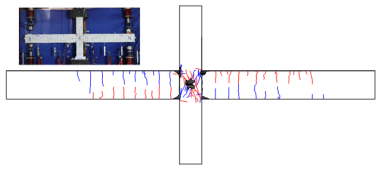

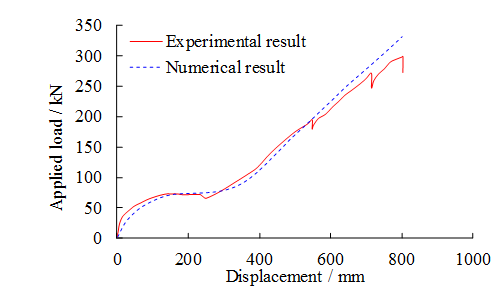

The experiments are conducted following the alternate path (AP) method as specified in the progressive collapse design guidelines [11-13]. In the AP method, column removal scenarios are assumed to study the progressive collapse responses of the remaining structures. A typical testing procedure is composed of the removal of a column and the subsequent monotonic loading, which aims to quantify the load carrying capacity of the remaining structures. Such testing protocol has been commonly used in many existing studies [27, 31, 41].

A middle column removal scenario is considered in the progressive collapse tests and the experimental setup is shown in Figure 7b. For simplicity, one directional specimens were used in the progressive collapse tests. Some researchers have conducted experiments to evaluate the bi-directional effects of beam specimens on the structural progressive collapse resistance [27]. Their results indicated that the progressive collapse resistance of the bi-directional specimen equals the summation of the individual beams lying in the perpendicular directions. Note that when considering the bi-direction effects, the external unbalanced load increases as well. It is therefore reasonable to conduct the experiments of one-directional beams to evaluate structural progressive collapse resistances [31-32, 41].

The tested two-span substructure is fixed to the strong boundary columns. In order to ensure the boundary fixities, H-shaped steel is embedded in the boundary column and two constant forces of 500 kN are applied to the top of the boundary columns. A monotonic concentrated load is then applied to the stub of the removed column to simulate the progressive collapse of the substructure subject to the middle-column removal. The loading process is displacement-controlled. At the same time, rotational restraints are installed in place of the removed column to prevent rotation of the column stub along the X and Z axes as shown in Figure 7b. Similar to the seismic cyclic test, six typical sections (Sections P-A to P-F) are defined on the specimens to better describe the experimental results as shown in Figure 7b.

2.4 Material properties

The material properties of the specimens are provided in Tables 1. Specimens S-RC6, S-RD1, P-RC6, and P-RD1 are cast with C30-grade concrete. Note that it is regulated in the Chinese code [39] that the concrete strength used in the prestressed concrete structures should not be below C40-grade (i.e., the compressive strength determined from the standard cube tests is 40 MPa). Therefore, the C40-grade concrete is used for Specimens S-PC6 and P-PC6 while the reinforcing details of the two specimens remain the same as those of S-RC6 and P-RC6, respectively. Note that concrete with the same strength is used for the RC specimens (i.e., S-RC6 and S-RD1), and hence it is rational to demonstrate the influence of the progressive collapse design on the seismic responses based on the test results of RC specimens. Plain round rebars are used for both the longitudinal and stirrup reinforcement in all the specimens. The PT tendons in Specimens S-PC6 and P-PC6 have an equivalent diameter of 12.7 mm. The experimentally measured tensile strength of the PT tendon is 1993 MPa. The prestressing forces in Specimens S-PC6 and P-PC6 are determined referring to the existing studies of self-centering prefabricated concrete frames [16-17]. The measured initial stress ratios of the PT tendons (i.e., the ratio between the initial stress and the tensile strength of the PT tendon) in Specimens S-PC6 and P-PC6 are 42% and 34%, respectively.

Table 1. Material properties

|

Reinforcement*1 |

||||||

|

Diameter / mm |

Yield strength fy / MPa |

Ultimate strength fu / MPa |

Elongation ratio / % |

|||

|

F4 |

720 |

720 |

4 |

|||

|

F8 |

300 |

460 |

38 |

|||

|

F10 |

360 |

535 |

34 |

|||

|

F12 |

369 |

520 |

39 |

|||

|

F14 |

370 |

515 |

31 |

|||

|

Steel components |

||||||

|

Thickness / mm |

Yield strength fy / MPa |

Ultimate strength fu / MPa |

Elongation ratio / % |

|||

|

8 (Steel jacket) |

449 |

518 |

39 |

|||

|

8 (Steel angle) |

305 |

454 |

41 |

|||

|

10 (Shear plate) |

313 |

537 |

40 |

|||

|

Concrete*2 |

||||||

|

Specimen |

Compressive strength fcu,150mm / MPa |

Specimen |

Compressive strength fcu,150mm / MPa |

|||

|

S-RC6 |

28.3 |

P-RC6 |

32.5 |

|||

|

S-RD1 |

28.3 |

P-RD1 |

32.5 |

|||

|

S-PC6 |

51.9 |

P-PC6 |

51.9 |

|||

Note: *1: Plain round bars were used in all the specimens. *2:The concrete compressive strength is determined by testing the standard cubes with a size of 150 mm ¡Á 150 mm ¡Á 150 mm, the mean value of three cubes is taken as the compressive strength.