|

5. Conclusions

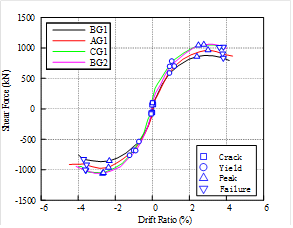

Four spatial sandwich beam-column joints with different concrete strength ratios were tested under skew cyclic loads.

Based on the experimental and analytical results, the following conclusions

can be made.

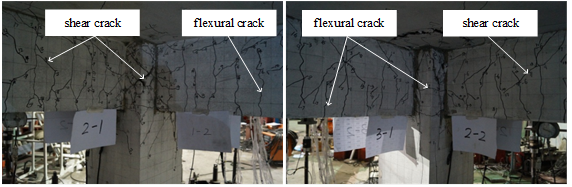

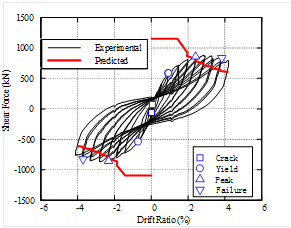

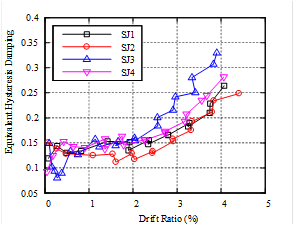

(1) The failure modes of all the sandwich joints are in form of joint shear failure, subsequent to the flexural yielding of the beams, while the ductility coefficient is greater than 3.0 which satisfies the ductility demands.

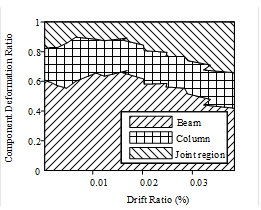

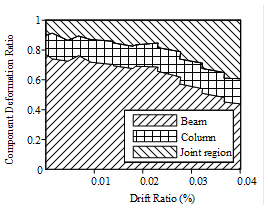

(2) Compared to the joints with lower concrete

strength ratios a, the specimen with the larger ratio features larger deformation at the joint.

(3) Based on the softened strut-and-tie model, a shear strength model of spatial

sandwich joints, taking into account the effects of concrete strength ratio, the floor slabs and the

plastic region of beams, is proposed herein. The predicted shear strengths are

compared with the test results in this work and those in the literature. The comparison indicates that the proposed equations can accurately predict the shear strengths of the sandwich beam-column joints with higher accuracy than other available models. Notwithstanding, further

study is necessary to more general situations where the maximum load applied

at a different angle or different loading histories in the two orthogonal

directions.

Acknowledgement

This work was financially supported by the

National Natural Science Foundation of China (No. 51778341) and the National

Key R&D Program (No. 2017YFC0702902).

Compliance with Ethical Standards

Funding: This study was funded by the National Natural Science Foundation of China (grant

number 51778341) and the National Key R&D Program (grant number 2017YFC0702902).

Conflict of Interest: The authors declare that they have no conflict of interest.

References

1.

Lu

X, Lu XZ, Guan H, Xie LL (2016) Application of earthquake-induced collapse

analysis in design optimization of a super-tall building. The Structural Design

of Tall and Special Buildings, 25(17): 926-946.

2.

Bianchini

AC, Woods RE, Kesler CE (1960) Effect of floor concrete strength on column

strength. ACI Journal, 31(11): 1149-1169.

3.

ACI

Committee 318-14 (2014) Building code requirements for structural concrete

(ACI 318-14) and commentary. American Concrete Institute, Farming Hills, MI.

4.

Ospina

CE, Alexander SDB (1998) Transmission of interior concrete column loads through

floors. Journal of Structural Engineering, 124 (6): 602-610.

5.

Lee

JH, Yoon YS (2012) Prediction of effective compressive strength of corner

columns composing weaker slab-column joint. Magazine of Concrete Research,

64(12): 1113-1121.

6.

Shin

HO, Yoon YS, Cook WD, Mitchell D (2016) Enhancing the performance of UHSC

columns intersected by weaker slabs. Engineering Structures, 127: 359-373.

7.

Shin

HO, Yoon YS, Mitchell D (2017) Axial load transfer in non-slender ultra-high-strength

concrete columns through normal-strength concrete floor slabs. Engineering

Structures, 136: 466-480.

8.

Yu

Q, Li SM (2004) Research on frame¡¯s joint that concrete strength of core is

inferior to that of column. Journal of Tongji University (Natural Science),

32(12): 1583-1588. (in Chinese)

9.

Zhao

M, Su XZ, Lu DY, Wang D (2005) Seismic properties of RC frame sandwich type

joints. Proceedings of 13th World Conference on Earthquake Engineering, Canada.

10.

Xu B, Cheng MK, Zhang

ML, Qian JR (2006) Experimental study on behavior of reinforced concrete beam-column

joint with lower core concrete. Industrial Construction, 36(6): 18-22. (in

Chinese)

11.

Yang ZH (2007) Seismic

behavior and design method of RC sandwich beam-column joints. Ph.D. Dissertation,

Chongqing University. (in Chinese)

12.

Li YM, Liu JW (2010)

Pseudo-static test for reinforced concrete sandwich beam-column joints, Journal

of Building Structures, 31(12): 74-82. (in Chinese)

13.

Yan WM, Hou LQ, Zhang

JB, Chen SC (2017) Seismic performance of space interior joints with different

concrete strength and shear capacity calculation. Journal of Building Structures,

38(2): 117-125. (in Chinese)

14.

Yang ZH, Li YM, Liu

JW (2010) Seismic load tests on reinforced concrete beam-column sandwich joints

with strengthening measures. Fourth International Conference on Experimental

Mechanics, Proc. of SPIE Vol. 7522 752264-1.

15.

Ministry of Housing

and Urban-Rural Development of the People's Republic of China (2010) Code

for design of concrete structures (GB 50010-2010). China Architecture &

Building Press, Beijing.

16.

Xie LL, Lu XZ, Guan

H, Lu X (2015) Experimental study and numerical model calibration for earthquake-induced

collapse of RC frames with emphasis on key columns, joints and overall structure.

Journal of Earthquake Engineering, 19(8): 1320-1344.

17.

Gamble LW, Klinar DJ

(1991) Test of high strength concrete columns with intervening floor slabs.

Journal of Structural Engineering, 117(5): 705-716.

18.

Kimreth M, Li B, Imran

I (2012) Seismic performance of lightly reinforced concrete exterior beam-column

joints. Advances in Structural Engineering, 15 (10): 1765-1780.

19.

Liu, A (2001) Seismic assessment and retrofit

of pre-1970s reinforced concrete frame structures. Ph.D. Dissertation, University

of Canterbury Civil Engineering.

20. Ministry of Housing

and Urban-Rural Development of the People's Republic of China (2010) Code

for seismic design of buildings (GB 50011-2011). China Architecture &

Building Press, Beijing.

21. ASCE. (2016). Minimum

design loads for buildings and other structures (ASCE/SEI 7-16). American

Society of Civil Engineers, Reston, Virginia.

22. Steelman JS, Hajjar

JF (2009) Influence of inelastic seismic response modeling on regional loss

estimation. Engineering Structures, 31(12): 2976-2987.

23. Park S, Mosalam KM.

(2013) Experimental investigation of nonductile RC corner beam-column joints

with floor slabs. Journal of Structural Engineering, 139(1):1-14.

24. Risi MTD, Verderame

GM (2017) Experimental assessment and numerical modelling of exterior non-conforming

beam-column joints with plain bars. Engineering Structures, 150: 115-134.

25. Ministry of Housing

and Urban-Rural Development of the People's Republic of China (2015) Specification

for seismic test of buildings (JGJ/T 101-2015). China Architecture & Building

Press, Beijing. (in Chinese).

26. Liao FY, Han LH, Tao

Z. (2014) Behaviour of composite joints with concrete encased CFST columns

under cyclic loading: Experiments. Engineering Structures, 59(2), 745-764.

27. ASCE (2013) Seismic

Evaluation and Retrofit of Existing Buildings (ASCE/SEI 41-13). American Seismic

Evaluation and Retrofit of Existing Buildings, Reston, Virginia.

28.

Shafaei J, Hosseini

A, Marefat MS, Ingham JM, Zare H. (2017) Experimental evaluation of seismically

and non-seismically detailed external RC beam-column joints. Journal of Earthquake

Engineering, 21(5): 776-807.

29.

Kassem W (2016) Strut-and-tie

modelling for the analysis and design of RC beam-column joints. Materials

and Structures, 49(8): 3459-3476.

30.

Li B, Lam SS, Wu B,

Wang YY (2015) Effect of high axial load on seismic behavior of reinforced

concrete beam-column joints with and without strengthening. ACI Structural

Journal, 112(6): 713-723.

31.

Hwang SJ, Tsai RJ, Lam

WK, Moehle JP (2017) Simplification of softened strut-and-tie model for strength

prediction of discontinuity regions. ACI Structural Journal, 114(5): 1239-1248.

32.

Okahashi Y, Pantelides

CP (2017) Strut-and-tie model for interior RC beam-column joints with substandard

details retrofitted with CFRP jackets. Composite Structures, 165: 1-8.

33.

Hwang SJ, Lee HJ (2002)

Strength prediction for discontinuity regions by softened strut-and-tie model.

Journal of Structural Engineering, 128(12): 1519-1526.

34.

Vecchio FJ, Collins

MP (1993) Compression response of cracked reinforced concrete. Journal of

Structural Engineering, 119(12), 3590-3610.

35.

Hwang SJ, Lee HJ (1999)

Analytical model for predicting shear strengths of exterior reinforced concrete

beam-column joints for seismic resistance. ACI Structural Journal, 96(5),

846-857.

36.

Hwang SJ, Lee HJ (2000)

Analytical model for predicting shear strengths of interior reinforced concrete

beam-column joints for seismic resistance. ACI Structural Journal, 97(1),

35-44.

37.

Xing GH, Liu BQ, Niu

DT (2013) Shear strength of reinforced concrete frame joints using modified

softened strut-and-tie model. Engineering Mechanics, 30(8): 60-66. (in Chinese)

38. Xing GH, He ZB, Niu

DT, Wu T, Liu X (2014). Analytical model for shear strength of reinforced

concrete beam-column-slab exterior joints. Journal of Central South University

(Science and Technology), 45(9): 3277-3282. (in Chinese)

39. Joh O, Goto Y, Shibata

T (1988) Behavior of three-dimensional reinforced concrete beam-column subassemblages

with slabs. Bulletin of the Faculty of Engineering, Hokkaido University.

40.

Lee JY, Kim JY, Oh GJ

(2002) Strength deterioration of reinforced concrete beam-column joints subjected

to cyclic loading. Engineering Structures, 31(9): 2070-2085.

41.

Joint ACI-ASCE Committee

352 (2002) Recommendations for design of beam-column joints in monolithic

reinforced concrete structures (ACI 352R-02). American Concrete Institute,

Farmington Hills, MI.

42.

CSA Committee A23.3

(2014) Design of concrete structures (CSA A23.3-14). Canadian Standard Association,

Toronto, Ontario.

Notations

|

Ac

|

gross-sectional area of the column;

|

|

As,

|

sectional areas of the top and bottom reinforcement

of the beam, respectively;

|

|

Asb

|

reinforcement area in the tension zone of the beam;

|

|

Asp

|

reinforcement area of the floor slab located within the beam effective

flange width;

|

|

|

area of the diagonal strut

|

|

Asvj

|

total sectional area of transverse reinforcements

within the effective width of the joint core zone in the loading direction;

|

|

|

distance between the centroid of resultant forces of longitudinal compressive

steel reinforcements and the extreme compression face of the beam.

|

|

as, bs

|

depth and width of the diagonal strut, respectively;

|

|

bb, hb

|

beam width and depth, respectively;

|

|

bc, hc

|

column width and depth, respectively;

|

|

bj, hj

|

effective width and height

of the core zone of the joint, respectively;

|

|

cb, cc

|

depth of the compression zone

of the beam and column, respectively;

|

|

|

distances between the extreme longitudinal reinforcement in the beams

and columns, respectively;

|

|

hbo

|

effective depth of beam;

|

|

|

distance between the centroids of upper and lower beam reinforcement;

|

|

Hc

|

height of column;

|

|

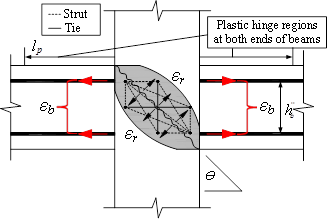

lp

|

length of the plastic hinge region of the beam;.

|

|

s

|

spacing of the transverse reinforcements

along the beam axis;

|

|

ts

|

thickness of the floor slab;

|

|

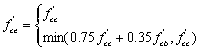

,

,

|

compressive strengths of concrete of the

beam and the column, respectively;

|

|

|

cylinder strength of concrete;

|

|

|

effective compressive

strength;

|

|

ft

|

design tensile strength of concrete;

|

|

fyv

|

design strength of shear reinforcement;

|

|

fyh, fyv

|

yield strength of the joint hoop reinforcement

and intermediate column bars, respectively;

|

|

fyb, fyp

|

yield strength of the beam reinforcement and slab reinforcement, respectively;

|

|

N

|

design axial force;

|

|

Nc

|

axial force acting on the column;

|

|

VACI

|

horizontal joint shear strength predicted

by ACI 318-14;

|

|

VCSA

|

horizontal joint shear strength predicted

by CSA A23.3-04;

|

|

Vjbf

|

horizontal joint shear strength when the

beam reinforcement yields;

|

|

Vj1

|

horizontal shear strength of type 1 joint;

|

|

Vjd

|

horizontal joint shear strength predicted

by Chinese Design Code for Concrete Structures;

|

|

Vsst

|

horizontal joint shear strength of the softened

strut-and-tie model;

|

|

|

horizontal joint shear strength of the modified

softened strut-and-tie model;

|

|

Vt

|

measured shear strength;

|

|

Eh

|

energy dissipated in each load cycle;

|

|

Ee

|

energy dissipation of an equivalent elastic cycle;

|

|

K

|

strut-and-tie index;

|

|

M /(V

h)

|

shear span ratio;

|

|

a

|

concrete strength

ratio;

|

|

q

|

angle between the diagonal strut and horizontal

axis;

|

|

gRE

|

seismic adjusting factor;

|

|

gh, gv

|

fractions of diagonal compression transferred

by the horizontal ties in the absence of the vertical ties and

the vertical ties in the absence of the horizontal ties, respectively;

|

|

,

,

|

balanced forces of the horizontal ties and

vertical ties, respectively;

|

|

,

,

|

indexes of the horizontal and vertical ties,

respectively;

|

|

D

|

lateral deformation at the top of the column;

|

|

eb

|

longitudinal strain of the beam reinforcement in the plastic hinge region

of the joint;

|

|

ebf

|

tensile strain of the beam at yielding;

|

|

er, ed

|

average principal tensile and compressive

strains in the joint, respectively;

|

|

ej

|

average concrete strain in the center of

the joint;

|

|

xh

|

equivalent hysteretic damping ratio;

|

|

hj

|

confinement effect factor of the orthogonal

beams;

|

|

n

|

softening coefficient of the

concrete;

|

|

f

|

strength reduction ratio;

|

|

fm

|

rotation angle of the column;

|

|

fpmp, fpmn

|

positive and negative plastic rotational angles,

respectively.

|

|

![]() . Bianchini et al.¡¯s work has subsequently been adopted as the design

guidelines of the American Concrete Institute [3]. In addition to the studies on the gravity

resistance [2, 4-7], significant amount of experimental and analytical studies

have also been performed to investigate the seismic performance of various sandwich

joints [8-14]. These studies revealed that the concrete strength reduction of

the joint had a certain degree of negative impact on the seismic performance

of the sandwich joints. However, sufficient seismic performance could be achieved

if the design parameters (such as the shear-compression ratio [14], axial load ratio [14], ratio

of column to beam concrete strength a, transverse reinforcement in the

joint) are well controlled. For some sandwich joints, strengthening measures

such as installing vertical or diagonal steel reinforcements may be required

[12, 14]. It should be noted however that these measures may inescapably lead

to complications in an already congested location in the joint.

. Bianchini et al.¡¯s work has subsequently been adopted as the design

guidelines of the American Concrete Institute [3]. In addition to the studies on the gravity

resistance [2, 4-7], significant amount of experimental and analytical studies

have also been performed to investigate the seismic performance of various sandwich

joints [8-14]. These studies revealed that the concrete strength reduction of

the joint had a certain degree of negative impact on the seismic performance

of the sandwich joints. However, sufficient seismic performance could be achieved

if the design parameters (such as the shear-compression ratio [14], axial load ratio [14], ratio

of column to beam concrete strength a, transverse reinforcement in the

joint) are well controlled. For some sandwich joints, strengthening measures

such as installing vertical or diagonal steel reinforcements may be required

[12, 14]. It should be noted however that these measures may inescapably lead

to complications in an already congested location in the joint.

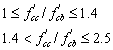

(14)

(14)