2. The Current TF method

2.1. Background

The TF method was first recommended in the British Standard [2-4] shortly after the Ronan Point event. This is followed by the Eurocode [5-6] which employs a similar tie force model and formulas. Recognizing a sufficient similarity between the US and British construction practices, the DoD 2005 [11] directly adopts the specifications of the British Standard with a suggestion of possible amendment based on further investigation [11]. In this study, the TF method as specified in the British Standard is studied in some detail for collapse resistance design of RC frame structures.

2.2. Basic provisions

In the TF method, the structural elements are assumed to be mechanically tied together thereby enhancing continuity, ductility, and development of alternate load paths. Tie forces are typically provided by the existing structural elements and connections, which are designed using conventional procedures to carry the standard loads imposed upon the structure. According to the location and function, the ties are classified into four types, viz internal, peripheral, ties to columns and walls, as well as vertical ties. The load paths of various types of ties are required to be the shortest while maintaining continuity and the required tie strength must be satisfied.

2.3. Basic tie strength

The current TF method is based on the basic tie strength Ft which is the minimum tensile force required for progressive collapse resistance. The strength of the four types of ties is obtained by multiplying the basic tie strength by a modification factor. As a result, the basic tie strength plays a highly important role in the entire TF methodology. In the current codes and standards, the basic tie strength is determined from the lesser of: (1) 4no+20 kN/m, where no is the number of stories in a structure, and (2) 60 kN/m. The first value is an empirical one from structural importance viewpoint. Using this value, structures with more stories would have more serious consequences due to progressive collapse. This thus leads to a larger requirement on the level of tie forces. The second value is obtained according to the following method - the failure mode of horizontal members, exhibiting a catenary behaviour, is assumed to effectively provide the required tie strength under limit state. It is believed that the horizontal members are able to function through catenary action thereby avoiding collapse. In such way, the complex indeterminate structure can be analyzed by transferring it locally into a determinate one at the location of a damaged vertical element, i.e. column. The analytical diagram for calculating the basic tie strength is illustrated in Figure 1 below.

|

|

|

Figure 1. Analytical diagram for calculating basic tie strength adopted in British code |

From Figure 1,

|

|

(1) |

where Ft is the total tensile force at mid-span; q is the uniformly distributed load applied to the top of the beam; L is the span length of the beam and Δ is the allowable deflection. Substituting typical values of L=5 m, q=5 kN/m2 and Δ=L/5 yields Ft=60 kN/m.

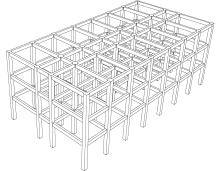

3. Simulation of Progressive Collapse and Analysis of Failure Mechanism

In this study, the analysis of progressive collapse is based on the finite element method. The results of a published laboratory test on a reinforced concrete planar frame are used to verify the numerical solution. Further, the collapse mechanism of the planar frame tested is also examined.

3.1. Finite element analysis

The fiber beam model THUFIBER [20] previously developed by the authors is used herein in conjunction with a commercial finite element software MSC.MARC [21] to simulate the collapse of a reinforced concrete planar frame tested by Yi et al. [22]. Through comparison with the test results, the reliability of using THUFIBER in collapse simulation is verified.

The four-span and three-story planar frame structure tested by Yi et al. [22] is shown in Figure 2, with detailed dimensions and test setup. In the experiment, a constant point load was applied to the top of the frame through a hydraulic jack. The removed/failed middle column in the ground floor, representing a collapse situation, was replaced by a passively loaded hydraulic jack. When the upper jack was balanced with load, the lower jack started to unload, by which the process of column removal can be replicated.

|

|

1: load cell 2: micrometer 3-1 to 3-4: displacement transducers 4-1 to 4-12: concrete strain gauges 5-1 to 5-4: sections having steel strain gauges |

|

Figure 2. Collapse test of planar frame (Yi et al. [22]) |

|

Figure 3(a) presents a comparison between the test results and the THUFIBER solution on the axial load versus the unloading displacement of the failed middle column. It is evident that the THUFIBER prediction is accurate. Shown in Figure 3(b) are the predicted horizontal displacements of the columns at first floor level affected by the downward displacement of the failed middle column. Again a good agreement with the test results is achieved, in particular at points 3-1 and 3-2.

|

|

|

|

(a) Axial load versus unloading displacement of failed middle column |

(b) Effect of downward displacement of middle column on horizontal displacement of columns at first floor level |

|

Figure 3. Comparison between analysis results and test data of frame specimen |

|

3.2. Analysis of collapse and failure mechanism

Shown in Figure 4(a) is the analytical diagram of the first floor beams supported directly by the failed middle column (see Figure 2). It should be noted that by virtue of symmetry, the axial forces at plastic hinges are identical at both beam ends (i.e. F1). This is also true for the axial forces at plastic hinges at mid-span (i.e. F2) as well as the moments (M1 and M2). Figure 4(b) presents the THUFIBER predictions of the internal forces (moments and axial forces) of the beam versus the unloading displacement of the failed middle column. Note also that due to symmetry, only the results of the left span (Sections 5-1 and 5-2 in Figure 2) are compared and reported herein.

|

|

F1: axial force at plastic hinges at beam ends F2: axial force at plastic hinge at mid-span M1: moment at plastic hinges at beam ends M2: moment at plastic hinge at mid-span P: concentrated load L: span of beam D: mid-span displacement q: rotation of plastic hinge |

|

(a) Analytical diagram for first floor beams above the failed middle column |

|

|

|

|

|

(b) Bending moment and axial force of first floor beams versus unloading displacement of failed middle column |

|

|

Figure 4. Analysis of collapse mechanism |

|

A further examination of Figures 4(b) reveals that the load-carrying process of the beams can be classified into three stages:

(1) Linear elastic stage (region 0A) - During this stage, the beam is restrained by the horizontal displacement and its cross-section is under the state of combined compression-bending. At the end of this stage, plastic hinges develop at the beam ends. The beam relies completely on the end moments in resisting the load.

(2) Plastic hinge developing stage (region AB) - plastic hinges undergo relatively large rotation due to an increase in the applied load. At this stage, large vertical deformation develops in the first floor beams and the outward horizontal restraints at beam ends release gradually. The internal force status of the beam cross-section also gradually changes from compression-bending to tension-bending when the middle column displacement reaches 150 mm. The applied load is now resisted by both the beam-end moments (in a large proportion) and the axial forces. This is because the vertical component of the tensile force is small due to the small magnitudes of the resultant as well as the deflection of the beam.

(3) Catenary action stage (region BC) - with continued increase in the applied load, the bending capacity at plastic hinges reduces dramatically thereby further increasing the deflection of the beam. At this stage, the applied load is carried by the beam, through tensile reinforcement, following a catenary action. With an increase in displacement, the vertical component of the beam axial force also increases. This leads to a further increase in load-carrying capacity until system collapses at point C.

Based on the above discussion of the three stages, it can be summarised that the applied load is initially resisted by the beam-end moments (so-called “beam action”) and then the axial forces (so-called “catenary action”). The change-over phase of the two actions occurs at around Point B, as shown in Figure 4(b). Yi et al. [22]’s experimental work reveals that the “beam action” under small deformation and the “catenary action” under large deformation can both be employed as a control state in collapse resistance design. However the relationships between deformation and “action” has not been quantified for general cases. It is therefore necessary to discuss in some detail the ultimate deformation for beam action and catenary action.

3.3. Ultimate deformation for beam action and catenary action

A typical moment-curvature relationship of a plastic hinge is presented in Figure 5(a). Corresponding to the ultimate moment Mu which is a 15% reduction of the maximum moment Mp, the rotation is defined as the ultimate rotation Ζu. According to the statistics on plastic hinge rotations provided by Xu [23] who summarised the test results of a total of 154 beams failed in flexural, the average yield rotation Ζy and the average ultimate rotation Ζu of a plastic hinge are 0.34“ and 3.4“ respectively. The corresponding deflections Δ of the beam are 0.006L and 0.06L respectively, while Δ and L are demonstrated in Figure 4(a). A simplified moment-curvature relationship of a plastic hinge is presented in Figure 5(b). It should be noted that the tie force of beams, upon losing flexural capacity due to larger rotation than Ζu, can be provided by tensile reinforcements until reaching fracture rotation Ζf. DoD2005 [11] recommends that for beams with a span-depth ratio greater than 5 in structures of medium to high safety classification, Ζf of a plastic hinge should be taken as 12º which is equivalent to 0.213L of the beam deflection. In the laboratory test of Yi et al. [22], Ζf was found to be 10.3º which is equivalent to 0.182L of the beam deflection. A Ζf of an equivalent deflection 0.2L is suggested in the current TF method [4, 6, 11]. Based on the above discussion, the corresponding ultimate deformations for beam and catenary actions are set to be 0.06L and 0.2L, respectively.

|

|

|

|

(a) Actual model |

(b) Simplified model |

|

My: yield moment; Mp: maximum moment; Mu: 85% of maximum moment; Ζy: yield rotation; Ζp: corresponding rotation under maximum moment; Ζu: ultimate rotation; Ζf: fracture rotation |

|

|

Figure 5. Moment-curvature relationship of plastic hinge |

|

![Figure 2. Collapse test of planar frame (Yi et al. [22])](./Improved_Tie_Force_Method_ES.files/image006.jpg)