|

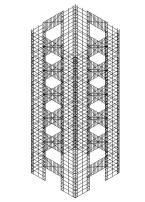

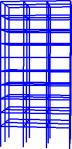

Whole collapse process of a high-rise frame-core

tube building under an extremely severe earthquake is simulated. With definitions

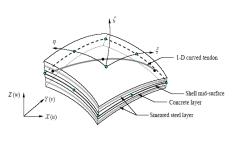

of elemental nonlinearity and contact arithmetic, the frame is modeled with

the fiber-beam-element and the core tube is modeled with multi-layer-shell-element.

The deformation and plastic hinges in different stages are shown in figure

21. At the first stage, the building vibrates slightly around its original

place and no damage occurs, shown as figure 21(a). At the second stage, shear

walls in the weak story fail due to large compressive-shear internal force.

And frame begins to yield and many plastic hinges appear around the weak story,

shown as figure 21(b). At the third stage and forth stage, the weak story

is destroyed and the whole structure comes into a complete collapse. The structure

above the failed weak story falls down and impact on the lower stories, which

results in a progressive collapse. Hence, the model gives a good simulation

on the failure mode and the whole collapse process of frame-core tube structure.

4.Conclusion

(1) The fiber-beam-element-model and shear

wall model based on multi-layer-shell-element are proposed and validated.

The simulation results agree well with the test results.

(2) Based on the models proposed, the progressive

process can be simulated by setting proper criterion to deactivate elements

and choosing appropriate algorithm of contact.

(3) The model and methodology proposed

in this paper is of some value to study the seismic performance and collapse

mechanism of buildings under severe earthquakes.

Acknowledgement

The research presented in this paper was

funded by the National Key Project of Scientific and Technical Supporting

Programs by Ministry of Science & Technology of China (2006BAK01A02-09).

REFERENCES

Asad U.Q.(2007). Study on Passive Control

of RC Frame with High Strength Reinforcements in the Columns. PhD thesis of

Tsinghua University, Beijing ,China.

Du X.L, Jia P. and Zhao J.(2007). Experimental

Study On Seismic Behavior of Reinforced Concrete Core Wall under Different

Axial Load Ratio. Journal of Harbin Institute of Technology 39:Sup2,

567-572.

Isobe, D., and Tsuda, M.(2003). Seismic

collapse analysis of reinforced concrete framed structures using the finite

element method. Earthquake Engineering and Structural Dynamics

32:13, 2027-2046.

Jia J.H. and Yu Y.L .(2001). Applying FEM

and DDA to Simulate the Demolition of Frame Structure. Blasting 18:1,27-30.

Jiang

J.J., He F.L., He Y.B., Lu X.Z.(2006).Finite element

method and application, Chinese Machine Press,Beijing, China.

Jiang

J.J., Lu X.Z., Ye L.P.(2005).Finite Elopement Analysis of Concrete Structures.

Tsinghua University Press, Beijing, China.

Kaewkulchai, G. and Williamson, E.B.(2004).Beam

element formulation and solution procedure for dynamic progressive collapse

analysis, Computers & Structures 82:7-8,639-651.

Khandelwal, K. and El-Tawil, S. (2005).

Multiscale

Computational Simulation of Progressive Collapse of Steel Frames.Proceedings

of the ASCE Structures Congress, May 2005.

L¨¦geron F. and Paultre, P.(2003). Uniaxial

confinement model for normal and high-strength concrete columns .

Structure Engineering 129:2,241¨C252.

L¨¦geron

F., Paultre P. and Mazar J.(2005) Damage mechanics modeling of nonlinear

seismic behavior of concrete structures. Engineering Mechanics

131:6, 946-954.

Li J.(2003). Experimental investigation

and theoretical analysis on seismic behavior of FS confined concrete columns

.PhD thesis of Tsinghua University, Beijing ,China.

Lu X.Z.

and Jiang J.J. (2001). Dynamic finite element simulation for the collapse

of world trade center. China Civil Engineering Journal 34:6,8-11.

Lynn, K.M. and Isobe, D. (2007).Structural

collapse analysis of framed

structures under impact loads using ASI-Gauss finite element method.

International Journal of Impact Engineer 34:9, 1500-1516.

Lynn, K.M.and Isobe, D. (2006).Finite

element code for impact collapse problems of framed structures. International

Journal of Impact Engineer 69:12,2538-2563.

Mattern, S., Blankenhorn, G.and Breidt,

M.(2007).Comparison of building collapse simulation results from finite element

and rigid body models. IUTAM Symposium on Multiscale Problems in Multibody

System Contacts, Springer Netherlands, 257-267.

Men

J., Lu X.Z., Song E.X. and Chen Z.Y.(2006). Application of multi-layer

model in shell wall computation. Protective Structure 28:3,9~13.

Miao

Z. W., Lu X. Z., Ye L. P., Ma Q. L.(2007). Simulation for the Collapse

of RC Frame Tall Buildings under Earthquake Disaster. Computational

Mechanics, Proceedings of ISCM 2007, July 30-August 1, Beijing,China.

Miao

Z.W.,Lu X.Z. ,LI Y. and Ye L.P.(2008). Analysis for Concrete Structures

under Complicated Stress Conditions Based on General Purpose FE Software

and Microplane Model. Journal of Shenyang Jianzhu University(Natural

Science) 24:1, 49-53.

Munjiza A.(2004) .The combined finite-discrete

element method for structural failure and collapse. Engineering Fracture

Mechanics 71:4-6, 469-483

Pekau, O.A. and Cui, Y. (2006).Progressive

collapse simulation of precast panel shear walls during earthquakes.

Computers & Structures 84:5-6, 400-412.

Qin D. and Fan L.C.(2001). Numerical Simulation

on Collapse Process of Reinforced Concrete Structures. Journal of Tongji

University 29:1,80-83.

Toi Y. and Isobe,D.(1999) Adaptively

shifted integration technique for finite element collapse analysis of

framed structures. International Journal for Numerical Methods

in Engineering.1999,36:14, 2323-2339.

Wang

X.L., Lu X.Z. and YE L.P..(2007). Numerical Simulation for the Hysteresis

Behavior of RC Columns under Cyclic Loads. Engineering Mechanics

24:12,76-81.

Wei Y.(2006). Research on seismic behavior

and design method for reinforced concrete core wall-steel frame hybrid structures

.PhD thesis of Tsinghua University, Beijing ,China.

Xuan G., Gu X.L. and Lu X.L..(2003). Numerical

analysis of collapse process for RC frame structures subjected to strong earthquakes.

Earthquake Engineering and Engineering Vibration 23:6,24-30.

Yi W.J., He Q.F. and Xiao Y.(2007). Collapse

performance of RC frame structure. Journal of Building Structures

28:5,104-109,117.

Zatar

W. and Mutsuyoshi H.(2002). Residual displacements of concrete bridge

piers subjected to near field earthquakes . ACI Structural Journal

99:6, 740-749.

Zhou J., Qu J.T. and Jia M.C.(2005). Numerical

Simulation of Concrete Frame Collapsing Process with PFC2D Program. Journal

of Seismological Research 28:3,288-293.

|