2.1. Fiber-beam element model

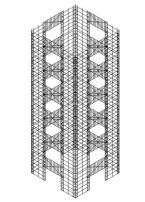

Fiber-beam element model has been widely accepted to model RC frames whose failure is predominately controlled by flexural behavior [17-18]. In the fiber-beam element model, the structural frames (beams and columns) are modeled with beam elements, and their sections are divided into individual fibers (Figure 1). Each fiber has its own uniaxial constitutive law, and different fibers in the same section follow the assumption that ¡°plane section remains plane¡±. The fiber-beam element model is capable of simulating the axial-flexural coupling of RC frames and is adaptive to different sectional shapes. The confinement effect of the stirrups in the columns can also be considered by using confined uniaxial constitutive relationship for core concrete and unconfined one for other concrete fibers. It is necessary to note that brittle shear failure is considered in the proposed fiber-beam mode. In other words, when the internal shear force exceeds the prescribed shear strength of the fiber-beam element, the strength and the stiffness of the element abruptly drop to zero.

The stress-strain model proposed by L¨¦geron et al. [19] is used in this study to model the backbone curve of concrete (Figure 2), which also considers the confinement of stirrups to concrete. Parabolic curves proposed by Mander et al. [20] are adopted to model the unloading and reloading paths of concrete where degradation of strength and stiffness due to cyclic loading (Figure 2) can be taken into account. An exponential model proposed by Jiang et al.[21] is used to model the softening branch of cracked concrete, with which the ¡°tension-stiffening effect¡± of reinforced concrete can be considered (Figure 2).

The stress-strain model proposed by Esmaeily and Xiao [22] is adopted to model the backbone curve of steel (Figure 3). The model proposed by L¨¦geron et al. [19] is adopted to model the unloading and reloading paths, in which the Bauschinger effect of steel can be considered (Figure 3).

Figure 1 Member section

Figure 2 Stress-strain curve of concrete

Figure 3 Stress-strain curve of steel

Based on the above material models, the fiber-beam element model is embedded into the general purpose FE software MSC.MARC with the user subroutine UBEAM [23]. Each RC frame element (beam or column) is subdivided into 6 to 8 fiber-beam elements to ensure sufficient accuracy.

Two compressive-flexural column tests, referred to as S-1 [24] and YW0 [25] respectively, are simulated to validate the proposed fiber-beam element model. Detailed dimensions of S-1 and YW0 are shown in Figures 4 and 5, respectively. It can be seen that S-1 has a larger reinforcement ratio (2.65%) and a smaller axial load ratio (0.03) whereas YW0 has a smaller reinforcement ratio (1.29%) and a larger axial load ratio (0.44). Figures 4 and 5 also indicate that the numerical simulations perform fairly well to capture the model yielding, hardening and unloading characteristics. Even for the final stage of the hysteretic response when the deterioration becomes evident, the discrepancies between the simulation and test results are still within the acceptable range in engineering practice.

Figure 4 Comparison between numerical simulation and test results of S-1

Figure 5 Comparison between numerical simulation and test results of YW0

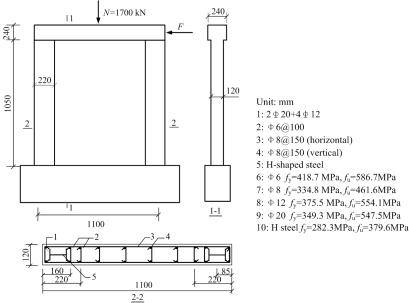

In order to further validate the reliability of the proposed model in predicting the actual strength deterioration, the progressive collapse test of a three-story four-bay planar frame carried out by Yi et al. [26] is simulated herein. The test setup and detailed dimensions are displayed in Figure 6. To represent the failure or removal of the middle column in the ground floor, the lower jacks unload gradually when the upper jack was balanced with load. Figure 7a shows a comparison between the experimental and simulated unloading curves for the middle column and Figure 7b presents the displacement comparison at selected points (located at the top of the columns on the first floor). Details of the simulation process can be found in Li et al. [27]. It is evident that the simulation results agree well with the experimental observations.

![Figure 6 Collapse test of the planar frame by Yi et al.[26]](./Collapse_Simulation_RC_High_Rise_Building_Earthquakes_EESD_2013.files/image012.gif)

Figure 6 Collapse test of the planar frame by Yi et al.[26]

(a) (b)

Figure 7 Comparison between simulation and test result of a four-bay three-story planar frame: (a) Unloading curve of middle column; (b) Displacement at the top of first-story columns

Furthermore, another compressive-flexural column test with large deterioration, conducted by Tang et al. [28], is also simulated to validate the capacity of the proposed fiber-beam model in predicting the strength deterioration in particular. Detailed dimensions and reinforcement arrangement are presented in Figure 8. The longitudinal reinforcement ratio of the specimen is 1.29% and the corresponding axial load ratio is 0.348. The hysteretic load-displacement comparison shown in Figure 8 indicates that the proposed fiber-beam model is able to replicate the strength deterioration within the considered acceptable range.

![Figure 8 Comparison between numerical simulation and test results by Tang [28]](./Collapse_Simulation_RC_High_Rise_Building_Earthquakes_EESD_2013.files/image018.gif)

Figure 8 Comparison between numerical simulation and test results by Tang [28]