|

Strengthening effect analysis

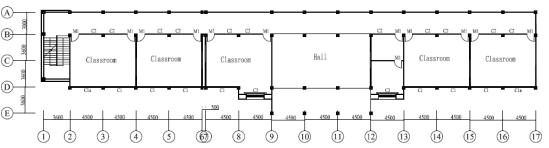

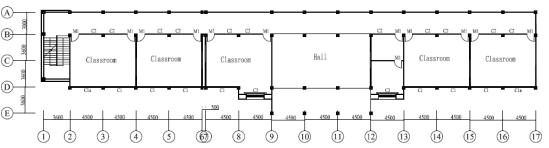

A typical RC frame classroom building

(Figure 1), which is close to the Wenchuan Earthquake epicenter, is used as

an example to analyze the strengthening effect of the steel brace. The plan

for the classroom building is shown in Figure 4. The detailed phenomenon of

seismic damage and the detailed structural information are described by Lu et

al. [16]. A steel brace is assumed to be installed in the short axis

direction of the frame, along which the frame collapsed. Two schemes (i.e.,

X-shaped and A-shaped) for the steel brace installation are compared, as shown

in Figure 5. To study the influence of the cross-section and numbers of the

braces on the structural collapse resistance, five load cases are compared as

follows:

(1)

Load Case 1: The section

of the steel brace is I25A, install a suit of braces every 2 frames (Load case

No: I25).

(2)

Load Case 2: The section

of the steel brace is I20A, install a suit of braces every 2 frames (Load case

No: I20).

(3)

Load Case 3: The section

of the steel brace is I20A, install a suit of braces every 4 frames (Load case

No: I20-1/2).

(4)

Load Case 4: The section

of the steel brace is I20A, install a suit of braces every 8 frames (Load case

No: I20-1/4).

(5)

Load Case 5: The section

of the steel brace is I20A, install a suit of braces every 12 frames (Load case

No: I20-1/6).

For Load Case 5, because the number

of classrooms is limited, it is actually impossible to install a suit of braces

every 6 classroom. Hence, this case was only studied theoretically.

Fig. 4 Plan of the Classroom Building

The earthquake ground motions, which

are used as the input of IDA, are 22 far-field ground motions suggested by FEMA

P695 [17]. Moreover, the widely used El-Centro ground motion is also

used as the input of the IDA. The structures are modeled with the THUFIBER Program

[14], and the influences of the foundations and floor slabs are considered.

The details of the model are described by Lu et al. [16]. To allow

for the influence of the steel stirrups, the confined concrete constitutive

law that is proposed by Bousalem and Chikh [18] is used to model

the core concrete. Because of the excellent nonlinear computing ability of the

THUFIBER program, the following collapse criterion is used: the structure is

deformed so much that the structure is unable to safely provide enough free

space [14].

|

|

|

|

X-shaped

|

A-shaped

|

|

Fig.5 Strengthening

scheme of the Classroom Building

|

Push-over results The push-over results of different load

cases are shown in Figure 6. As the number of braces increases, the stiffness

and bearing capacity are improved. This result is the positive effect of the

brace strengthening [3]. However, the ductility of the frame decreases with an increase in

the brace number because the brace will bring additional axial force to the

column. Because the axial force ratio of the columns has approached to the ultimate

value [16], the additional axial force will result in a decrease

in the ductility of the frame. This is the negative effect of the brace strengthening

on the seismic resistance. Because both positive effect and negative effects

are observed in the push-over analysis, it is difficult to draw a conclusion

about the brace strengthening effect from the push-over results. Hence, collapsed

fragility analyses based on IDA for different load cases are analyzed as follows

to compare the effects of different strengthening schemes.

Fig.6 Push-over result of steel

brace strengthening scheme

Collapsed fragility analysis results The collapsed fragility analysis results of the steel

brace strengthening scheme are shown in Figure 7. In Figure 7, the vertical

axis is the collapsed possibility, which is the proportion of collapsed ground

motion records and total ground motion records at a given seismic intensity.

The horizontal axis is the seismic intensity, and the spectral acceleration

at structural fundamental period Sa(T1)

is used as the intensity measure. According to the work in Ref [3], [14] and

[17], Sa(T1) can reduce the dispersion of

the IDA results. It can be observed from Figure 7 that after steel brace strengthening,

the collapse possibility is reduced obviously under the maximal considered earthquake

(Sa(T1)=Sa(T1),MCE).

When Sa(T1)=2Sa(T1),MCE,

the strengthening effect is also obvious. However, when Sa(T1)

is larger than 4 times Sa(T1),MCE

(Sa(T1)>4Sa(T1),MCE),

the collapse possibility unexpectedly increases. The reasons for this increase

are as follows.

|

|

|

|

|

|

|

|

|

Fig.7 Collapse possibility curves of conventional

brace strengthening scheme

For RC frame structures strengthened

with braces, the braces have two effects on the seismic resistance of the structure.

On one hand, the structural bearing capacity is enhanced, and the energy dissipation

capacity is improved due to the plastic deformation of the brace. Therefore,

the structural collapses resistance is improved. On the other hand, the structural

stiffness is enhanced, so the seismic load is increased. Furthermore, the axial

forces of columns are increased due to the axial load of the brace. Therefore,

the deformation capacities of columns are reduced, which will weaken the structural

collapse resistance.

In general, if the energy input of ground

motion is relatively stable or the ground motion intensity is small, the energy

dissipation capacity of the braces will be fully used. Hence, the structural

collapse resistance will be improved. However, if the earthquake is pulse-type

or the ground motion intensity is large, the structure will collapse very quickly,

and the energy dissipation capacity of the braces will not be fully used. In

this situation, the negative effect due to the increasing axial force in the

column will be a dominant factor.

Typical failure modes of the steel brace¨Cstrengthened structures are shown in Figure 8. Figure 8a

shows the failure mode in which the collapse resistance is improved after strengthening;

the input ground motion record is from Kobe, Japan, 1995. Without strengthening,

the structure will collapse when Sa is larger than 2.5 m/s.

After strengthening, the structure will collapse when Sa is

larger than 4.9 m/s. Subjected to this ground motion, the structure has experienced

a few of cycles of vibration before it collapses, and the energy dissipation

capacity of the braces has been fully used. The structural plastic hinges are

uniformly distributed, which also provides a better energy dissipation capacity.

In Figure 8b, the input ground motion record is from Duzce, Turkey, 1999. Without

strengthening, the structure will collapse when Sa is larger

than 7.35 m/s. After strengthening, the structure will collapse when Sa

is larger than 4.9 m/s. Hence, the structural collapse resistance is reduced

because the Duzce record is a pulse-type earthquake. After the first pulse,

the top of the side column in the bottom story has been destroyed because the

deformation is too large. The energy dissipation capacity of the braces cannot

be fully utilized. Moreover, the number of plastic hinges inside the building

is also very limited. The energy dissipation capacity of the structure is not

fully developed.

|

|

|

|

(  Plastic hinges

in beams£¬ Plastic hinges

in beams£¬  Plastic hinges

in columns£¬ Plastic hinges

in columns£¬  Destroy position) Destroy position)

|

|

(a) Kobe, Japan, 1995 earthquake input

|

(b) Duzce,

Turkey, 1999 earthquake input

|

|

Fig. 8 Failure mode of a conventional

brace strengthened¨Cstructure

|

The collapse possibilities of different

steel brace strengthening schemes are shown in Table 2. In Table 2, the collapse

margin ratio (CMR) is defined as:

(1)

(1)

where Sa(T1)50%collapse

is the intensity of the input motions under which 50% of the ground motions

will cause structural collapse. Sa(T1)MCE

is the maximal considered earthquake intensity. The larger CMR is, the better

the structural collapse resistance is. The CMR does not change monotonically

with the brace number. Therefore, there is an optimal number for the brace strengthening

scheme. Among these cases, Load Case 4 is the best choice.

Tab. 2 Collapse possibility of the conventional

brace-strengthening scheme

|

Load cases

|

X-shaped

|

A-shaped

|

|

CMR

|

Sa(T1)/Sa(T1),MCE

|

CMR

|

Sa(T1)/Sa(T1),MCE

|

|

1.0

|

2.0

|

1.0

|

2.0

|

|

I25

|

4.05

|

0.0%

|

0.0%

|

4.05

|

0.0%

|

0.0%

|

|

I20

|

3.91

|

0.0%

|

0.0%

|

4.28

|

0.0%

|

0.0%

|

|

I20-1/2

|

4.02

|

0.0%

|

0.0%

|

4.49

|

0.0%

|

0.0%

|

|

I20-1/4

|

4.91

|

0.0%

|

0.0%

|

4.49

|

0.0%

|

0.0%

|

|

I20-1/6

|

4.74

|

0.0%

|

1.5%

|

4.49

|

0.0%

|

0.0%

|

To compare the influence of different

brace arrangements, the I20 Load Case is used as an example, and the comparison

of the collapse possibilities is shown in Figure 9. With the same number and

section of braces, the strengthening effect of the A-shaped brace is better

than that of the X-shaped brace. This result is obtained because the X-shaped

braces will bring more axial force to the bottom columns, which is unfavorable

for structural collapse resistance.

Fig.

9 Comparison of the collapse possibility curves of steel

brace strengthening schemes

|