|

Conclusions

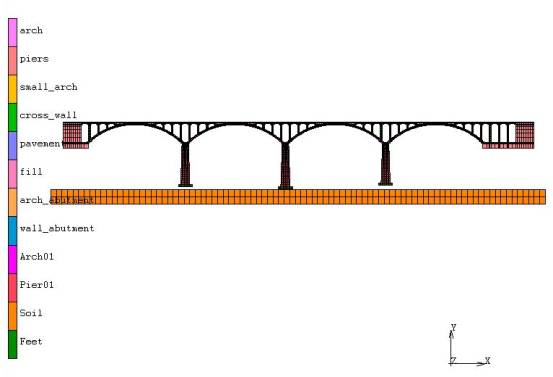

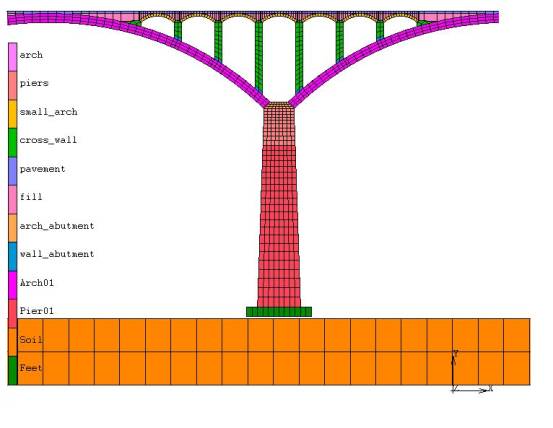

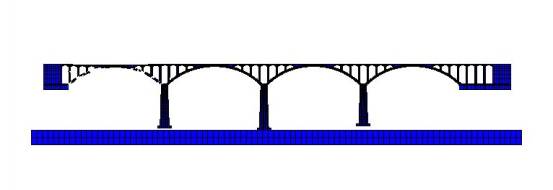

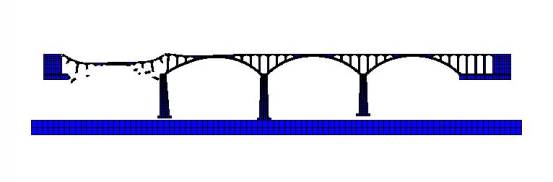

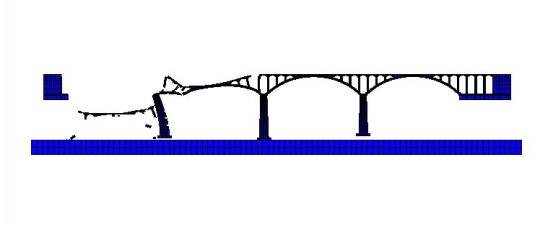

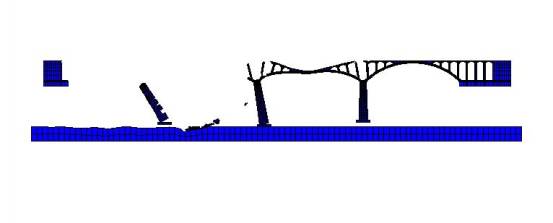

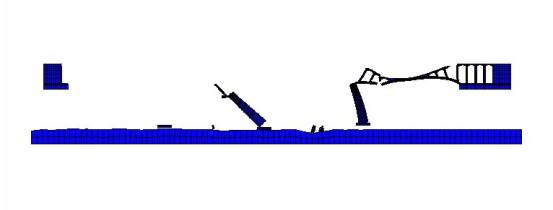

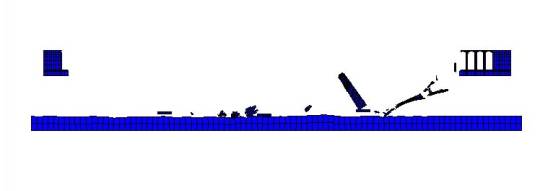

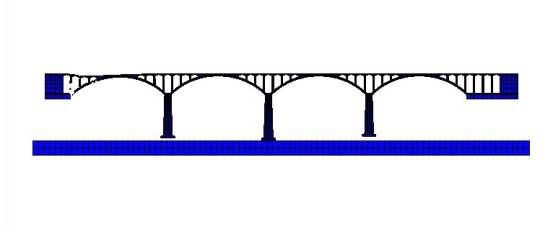

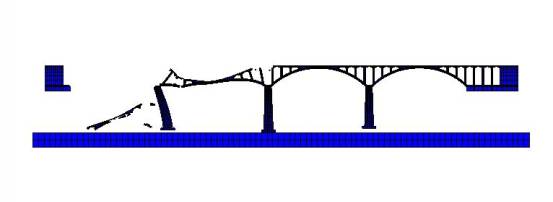

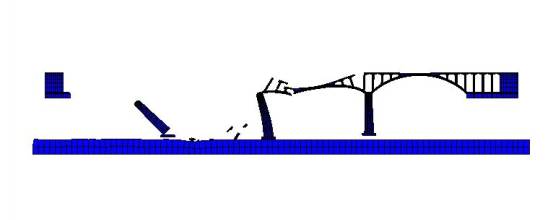

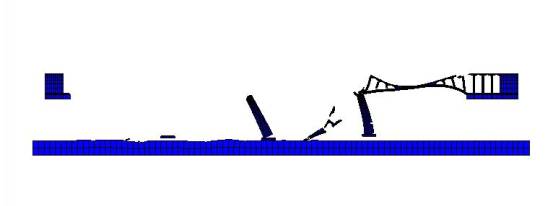

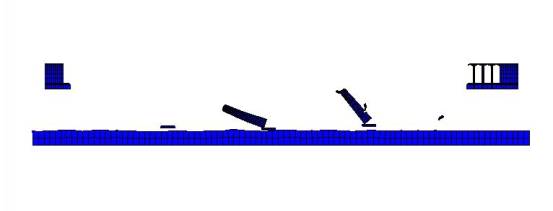

Based on the

FE simulation of the progressive collapse of a typical stone arch bridge,

this study replicated the collapse process and evaluated the importance indices of all the

structural elements. The following conclusions can be drawn:

1.

An effective FE simulation of the complete

progressive-collapse process of a stone arch bridge was performed;

2.

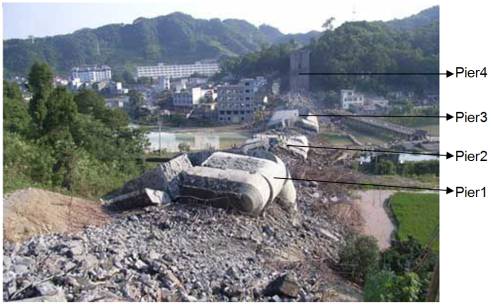

The FE simulation of the stone arch bridge

collapse agreed well with the site investigation of the accident, which provides

favorable references to determine the possible reasons for the collapse;

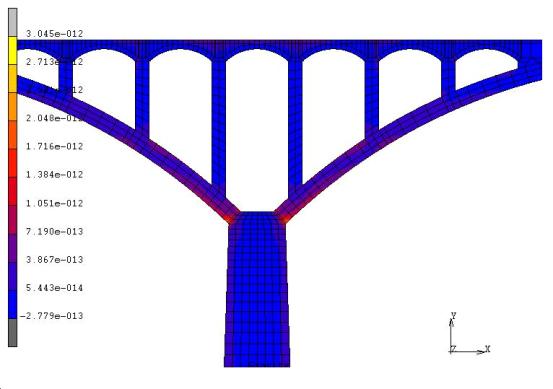

3.

A reliable and simple identification method

of the critical regions based on the generalized structural stiffness was proposed. The identified critical

regions of a stone arch bridge can be used to facilitate a rational design,

construction, inspection and maintenance practice, which would thereby lead

to prevention strategies and minimize the likelihood of progressive collapses

of arch bridges.

Acknowledgements

This study is funded by the West Transport

Project of Ministry of Transport of China (Grant No. 2008-318-223-43),

Major S&T Special Project of Ministry of Transport of PR China (Grant

No. 2011-318-223-170), Tsinghua University Research Funds (Grant No. 2010THZ02-1),

and Program for New Century Excellent Talents in University (Grant No.

NCET-10-0528).

References

Agarwal, J., Blockley, D. and Woodman N. (2001). ¡°Vulnerability of 3-dimensional

trusses.¡± Struct. Safety, 23(3), 203-220.

Baylot, J. T. (1997). ¡°Numerical simulation of alternate scenario for

Khobar Towers.¡± Proc., 68th Shock and Vibration Symposium (Limited Distribution),

Hunt Valley, MD.

Bažant, Z. P. and Planas, J. (1997). Fracture and size effect

in concrete and other quasibrittle materials, CRC Press, Boca Raton.

Biezma, M. V. and Schanack, F. (2007). ¡°Collapse of steel bridges.¡±

J. Perform. Constr. Facil., 21(5), 398-405.

Cavicchi, A. and Gambarotta, L. (2005). ¡°Collapse analysis of masonry

bridges taking into account arch¨Cfill

interaction.¡± Engineering Structures, 27(4), 605-615.

Chen, M. X. (2008). ¡°On stone arch bridge from the Dixi bridge accident

in fenghuang.¡± Highway Engineering, 33(3), 1-9 (in Chinese).

Drosopoulos, G. A., Stavroulakis, G. E. and Massalas, C. V. (2006). ¡°Limit

analysis of a single span masonry bridge with unilateral frictional contact

interfaces.¡± Engineering Structures, 28(13), 1864-1873.

Fanning, P. J. and Boothby, T. E. (2001). ¡°Three-dimensional modeling and full-scale testing of

stone arch bridges.¡±

Computers & Structures,

79(29-30), 2645-2662.

Farrar, C. R. and Jauregui, D. A. (1998). ¡°Comparative study of damage

identification algorithms applied to a bridge: I. Experiment.¡± Smart Mater.

Struct., 7(5),704-719.

Gharaibeh, E. S., Frangopol, D. M. and Onoufriou, T. (2002). ¡°Reliability-based

importance assessment of structural members with applications to complex structures.¡±

Computers & Structures, 80(12), 1113-1131.

Heyman, J. (1969). ¡°The safety of masonry arches.¡± International Journal of Mechanical Sciences, 11(4), 363-385.

Heyman, J. (1993). ¡°The collapse of stone vaulting.¡± Proc.,

3th Int. Conf. on Structural Studies, Repairs

and Maintenance of Historical Buildings, Computational Mechanics Publications, Bath, UK, 327-338.

Hu, X. B. (2007). ¡°Studies on the progressive-collapse resistant behavior

of the new type polyhedral space frame.¡± Ph.D. thesis, Tsinghua University,

Beijing, China (in Chinese).

Isobe, D. and Tsuda, M. (2003). ¡°Seismic collapse analysis of reinforced

concrete framed structures using the finite element method.¡± Earthquake

Engineering & Structural Dynamics, 32(13), 2027-2046.

Ji, Z. Y. and Lin, S. P. (1995). ¡°Fuzzy evaluation for residual carrying

capacity of damaged structures.¡± Journal of Building Structure, 16

(2), 51-57 (in Chinese).

Jiang, J. J., Lu, X. Z. and Ye, L.

P. (2005). Finite element analysis of concrete structures, Tsinghua

University Press. Beijing, China (in Chinese).

Kaewkulchai, G. and Williamson, E. B. (2004). ¡°Beam element formulation

and solution procedure for dynamic progressive collapse analysis¡±. Computers

& Structures, 82(7-8), 639-651.

Karapitta, L., Mouzakis, H. and Carydis P. (2010). ¡°Explicit finite-element

analysis for the in-plane cyclic behavior of unreinforced masonry structures.¡±

Earthquake Engineering & Structural Dynamics, 40(2), 175-193.

Khandelwal, K. (2008). ¡°Multi-scale computational simulation of progressive

collapse of steel frames.¡± P.h.D. Thesis, University of Michigan, Michigan,

USA.

Krauthammer, T., Hall, R. L., Woodson, S. C., Baylot, J. T., Hayes, J.

R., and Sohn, Y.(2002). ¡°Development of progressive-collapse analysis procedure

and condition assessment for structures.¡± National Workshop on Prevention

of Progressive-collapse in Rosemont, Washington, D.C.

Kumar, P. and Bhandari, N. M. (2005). ¡°Non-linear finite element analysis

of masonry arches for prediction of collapse load.¡± Structural Engineering

International, 15(3), 166-175.

LeBeau, K. H. and Wadia-Fascetti, S. J. (2007). ¡°Fault tree analysis of

schoharie creek bridge collapse.¡± J. Perform. Constr. Facil., 21(4),

320-326.

Liu, C. M. and Liu, X. L. (2004). ¡°Study on the comprehensive assessment

method of structural reliability.¡± Sichuan Building Science, 30(4),

46-58 (in Chinese).

Liu, C. M. and Liu, X. L. (2005). ¡°Stiffness-based evaluation of component

importance and its relationship with redundancy.¡± Journal of Shanghai Jiaotong

University, 39(5), 746-750 (in Chinese).

Lofti, H. R. and Shing, P. B. (1994). ¡°Interface model applied to fracture

of masonry structures.¡± J. Struct. Eng., 120(1), 63-80.

Long, H. T. (2007). ¡°News: 64 people died in collapse accident of Fenghuang bridge.¡±<http://www.hn.xinhuanet.com/jdwt/2007-08/20/content_10902812.htm> (Aug. 4, 2010)

(in Chinese).

Loo, Y. C. and Yang, Y. (1991). ¡°Cracking and failure analysis of masonry

arch bridges.¡± J. Struct. Eng., 117(6), 1641-1659.

Lu, X., Lu, X. Z., Zhang, W. K. and

Ye, L. P. (2011). ¡°Collapse simulation of a super high-rise building

subjected to extremely strong earthquakes.¡± Science China Technological

Sciences, 54(10), 2549-2560.

Lu, X. Z., Lin, X. C. and

Ye, L. P. (2009). ¡°Simulation of structural collapse with coupled

finite element-discrete element method.¡± Proc., Computational Structural

Engineering, Shanghai, 127-135.

Lynn, K. M. and Isobe, D. (2007a). ¡°Structural collapse analysis of framed

structures under impact loads using ASI-Gauss finite element method.¡± International

Journal of Impact Engineer, 34(9), 1500-1516.

Lynn, K. M. and Isobe, D. (2007b). ¡°Finite element code for impact collapse

problems of framed structures.¡± International Journal for Numerical Methods

in Engineering, 69(12), 2538-2563.

Mattern, S., Blankenhorn, G. and Breidt, M. (2007). ¡°Comparison of building

collapse simulation results from finite element and rigid body models.¡± IUTAM

Symposium on Multiscale Problems in Multibody System Contacts, Springer,

Netherlands, 257-267.

Ministry of Transport of the People¡¯s Republic of China (MTPRC). (2005).

Code for design of highway masonry bridge and culverts, China Communications

Press, Beijing (in Chinese).

Ministry of Transport of the People¡¯s Republic of China (MTPRC). (2007).

Code for design of ground base and foundation of highway bridge and culverts,

China Communications Press, Beijing (in Chinese).

MSC.Marc. (2005a). Marc user¡¯s guide, Santa Ana,

California.

MSC.Marc. (2005b).Volume D: User subroutines and special routines,

Santa Ana, California.

MSC.Marc. (2005c). Volume A: Theory and user information,

Santa Ana, California.

Munjiza, A., Bangash, T. and John, N. W. M. (2004). ¡°The combined finite-discrete

element method for structural failure and collapse.¡± Engineering Fracture

Mechanics, 71(4-6), 469-483.

Nafday, A. M. (2008). ¡°System safety performance metrics for skeletal

structures.¡± J. Struct. Eng., 134(3), 499-504.

National Institute of Standards and Technology (NIST). (2008). ¡°Final

report on the collapse of world trade centre building 7.¡± <http://

wtc.nist.gov/media/NIST_NCSTAR_1A_for_public_comment.pdf>

(Aug. 8, 2010).

National Transportation Safety Board (NTSB). (2008). ¡°Highway accident

report: collapse of interstate 35W highway bridge.¡± <

http://www.ntsb.gov/publictn/2008/HAR0803.pdf>

(May 7, 2010)

Pekau, O. A. and Cui, Y. (2006). ¡°Progressive collapse simulation of precast

panel shear walls during earthquakes.¡± Computers & Structures,

84(5-6), 400-412.

Poston, R. W. and West, J. S. (2005). ¡°Investigation of the charlotte

motor speedway bridge collapse.¡± Proc., 2005 Structures Congress and the

2005 Forensic Engineering Symposium, ASCE, New York.

Rots, J. G. (1991). ¡°Numerical simulation of cracking in structural masonry.¡±

Heron 1991, 36(2), 49-63.

Scheer, J. (2000). Versagen von Bauwerken (Band 1: Br¨¨cken). Ernst

& Sohn, Berlin.

Scott, W. R. (1995). ¡°Reconstruction of the flood damaged Ness viaduct ¨C Inverness.¡±

Institution of Civil Engineers, 111(2), 135-137.

Thavalingam, A., Bicanic, N., Robinson J. I. and Ponniah D. A. (2001).

¡°Computational framework for discontinuous modelling of masonry arch bridges.¡±

Computers & Structures, 79(19), 1821-1830.

Wardhana, K. and Hadipriono, F. C. (2003). ¡°Analysis of recent bridge

failures in the United States.¡± J. Perform. Constr. Facil., 17 (3),

144-150.

Yao, L.S. (2008). Bridge engineering (2nd edition), China Communication

Press, Beijing, China (in Chinese).

Ye, L.

P., Lin, X. C., Qu, Z., Lu, X. Z. and Pan, P. (2010). ¡°Method of evaluating

element importance of structure system based on the generalized structural

stiffness.¡± Journal of Architectural and Civil Engineering,

27(1), 1-6 (in Chinese).

Zhang, L. M. and Liu, X. L. (2007). ¡°Network of energy transfer in frame

structures and its preliminary application.¡± China Civil Engineering Journal,

2007, 40(3), 45-49 (in Chinese).

Zhang, Y. and Li, L. S. (1997). ¡°Fuzzy comprehensive evaluation of reliability

of existing building structures.¡± Journal of Building Structure, 189(5),

12-20 (in Chinese).

Zhou, J. T., Liu, S. M. and Li, Y. J. (2008). Reinforcement and reconstruction

of masonry arch bridge, China Communication Press, Beijing (in Chinese).

Table

1. Material Parameters of Different Structural Components

|

Structural components

|

Young¡¯s modulus (MPa)

|

Yielding strength (MPa)

|

Cracking strength (MPa)

|

Poisson ratio

|

Density (kg/m3)

|

|

Primary arch

|

13,293

|

10.13

|

0.32

|

0.20

|

2500

|

|

Transverse wall

|

7,300

|

5.25

|

0.13

|

0.20

|

2500

|

|

Spandrel arch

|

7,300

|

6.30

|

0.13

|

0.20

|

2500

|

|

Pier

|

11,256

|

8.58

|

0.28

|

0.20

|

2400

|

|

Foundation

|

25,500

|

13.40

|

1.54

|

0.20

|

2000

|

|

Filler

|

7,300

|

1.12

|

0.11

|

0.20

|

2300

|

|

Pavement

|

30,000

|

20.10

|

2.01

|

0.20

|

2500

|

|