Debonding failure strength in RC beams strengthened with FRP for shear

Paper download

Size

Effects for Reinforced Concrete Beams Strengthened in Shear with CFRP

Strips

Journal

of Composites for Construction,2010

Abstract: The principal motivation of this study is to obtain a clear understanding of size effects for fiber-reinforced polymer (FRP) shear-strengthened beams. The experimental program consists of seven beams of various sizes grouped in three test series. One beam of each series is used as a benchmark and its behavior is compared with a beam strengthened with a U-shaped carbon FRP (CFRP) jacket. The third test series includes an additional beam strengthened with completely wrapped external CFRP sheets. The experimental results show that the effective axial strains of the CFRP sheets are higher in the smaller specimens. Moreover, with a larger beam size, one can expect less strain in the FRPs. A nonlinear finite-element numerical analysis is developed to model the behavior of the CFRP shear-strengthened beams. The numerical model is able to simulate the characteristics of the shear-strengthened beams, including the interfacial behavior between the concrete and the CFRP sheets. Three prediction models available in current design guidelines for computing the CFRP effective strain and shear contribution to the shear capacity of the CFRP shear-strengthened beams are compared with the experimental results.

Influence

of concrete stress state on shear contribution of FRP strips on RC beams

Engineering Mechanics,

2008, 25(8): 127-132.

Abstract:

FRP (fibre reinforced polymer) debonding is one of the major failure

modes for reinforced concrete beams shear-strengthened with external

FRP strips. Currently, the properties of the FRP-concrete interface

based on pull-off tests are adopted in the capacity prediction of FRP

shear-strengthened reinforced concrete beams. However, the concrete

layers underneath FRP strips in these two cases are in different stress

states, and so are the behaviours of the FRP-concrete interfaces. As

a result, the FRP shear contribution may be over-estimated. This effect

is examined in this paper, and a reduction factor accounting for the

effect of the complex stress state in U jacketed RC beams is proposed

based on test results from literature. A comparison with test results

shows that better agreement is achieved using the proposed factor to

modify FRP shear contribution.

Key words: RC beams; shear strengthening; FRP-concrete interface;

tri-axial stress state; interface debonding

Abstract: The FRP-to-concrete interfacial debonding

is a fundamental key problem for the strengthening of RC structures

with externally bonded FRP sheets/plates. This paper presents the design

models and detail designs on the flexural or shear debonding of RC beams

strengthened with FRP sheets/plates, which is based on the latest experimental

and theoretical researches on the FRP-to-concrete interfacial constitutive

behavior, flexural and shear strengthening.

Keywords: FRP sheets/plates, strengthening, debonding, interface.

Numerical

modeling of FRP shear strengthened RC beams using compression field

theory

Proc. 3rd Int. Conf. for Composite in Civil Engineering

(CICE 2006), Miami, USA, 2006, 391-394.

Abstract: The modified compression field theory and an advanced bond-slip model are implemented in a general finite element analysis package to evaluate the shear behaviour of FRP strengthened reinforced concrete beams. The inclination angle of the critical shear crack is estimated and the debonding phenomenon is simulated. A close agreement is achieved between the predicted average FRP strains and those in a test beam reported in the literature. Further research is being conducted to simulate behaviour of FRP shear the interaction between the external FRP shear reinforcement and concrete.

keywords: Shear, FRP, strengthening, concrete, modified compression field theory (MCFT)

Debonding

Failure Strength in RC Beams Strengthened with FRP for Shear

Building

Structure, 36 (9), 2006, 31-36.

Abstract: Debonding failures always take place in reinforced concrete (RC) beams strengthened with externally bonded FRP against shear failure. Whilst the shear capacity may continue to increase after debonding for FRP wrapped beams, FRP debonding represents the ultimate failure state for most beams strengthened with U jacketing and side-bonding. This paper presents a review of existing studies on debonding failure. Using a rigorous local FRP-to-concrete bond-slip model, the stress distribution in FRP along the critical shear crack is then investigated by assuming several crack width distributions. A new design model is proposed. Compared with test data, the new model has similar accuracy with but is slightly conservative than Chen and Teng¡¯s model.

Key words: FRP, debonding, shear strengthening, reinforced concrete beam, shear strength

Numerical

Research On Shear Behaviors Of RC Beams Strengthened With U-Type FRP

Sheets

Engineering

Mechanics, 22(4).2005.155-162

Abstract:

The utilization of FRP in the shear strengthening for reinforced concrete

beams represents an effective way in upgrading the low loading capacity

of the beams due to the lack of web reinforcement. Based on the tests

data of seven beams, this paper presents analysis of FRP strengthened

RC beams using 3-D finite element model with the calculation performed

on ANSYS. The effects of various parameters on numerical results are

discussed with the bond strength bewteen FRP and concrete, shear transfer

coefficients for cracks finally determined. The numerical results shows

good agreement with the experimental results. To gain a better understanding

of the role FRP plays in the RC beam shear strengthing, further investigation

is conducted with respects to the distribution of strain in FRP under

each load level¡¢the FRP¡¯s contribution to the overall shear strength¡¢the

peeling-off process of FRP from the concrete¡¯s surface and the relationship

between the efficiency and the amount of FRP used in the shear strengthing.

Key

word: FRP; shear strengthening; finite element analysis; bond strength;

strain; peel-off process

Size

effect of shear contribution of externally bonded FRP U-jackets for

RC beams

Proc. International Symposium on Bond Behaviour of FRP

in Structures (BBFS 2005), Hong Kong, China, 2005. 371-380

ABSTRACT: It is well known that size effect exists in the shear strength of RC beams. Larger beams have a smaller nominal maximum shear strength. The size effect in RC beams shear strengthened with FRP has not been considered in existing predictive models. In these strengthened beams, the size effect may exist in the shear contributions of both RC beams and FRP. To better understand the shear strengthening and its corresponding size effect, a series of geometrically similar concrete beams strengthened with CFRP U-jackets were designed and tested in this study. The total shear strength of a strengthened RC beam is considered to consist of three components which are the shear contribution of the RC beam, and the direct and indirect shear contributions of the FRP. The direct shear contribution of FRP is obtained in this study with careful experimental measurements. An improved predictive model is proposed, which can obviously remove the size effect on direct FRP shear contribution. More studies are needed to quantify the indirect FRP shear contribution.

|

|

|

|

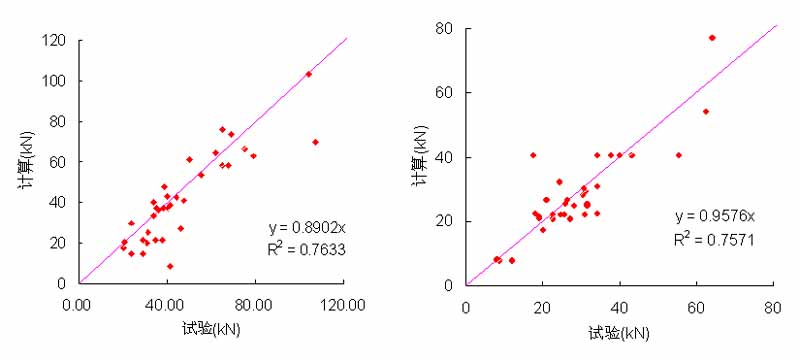

Comparison with other existing models |